Grid Distortion Test Targets

- Test Targets Help Identify Distortion in Imaging Systems

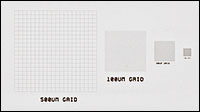

- Grid Spacings Available from 2 µm to 5000 µm

- Combined Resolution and Distortion Targets Available

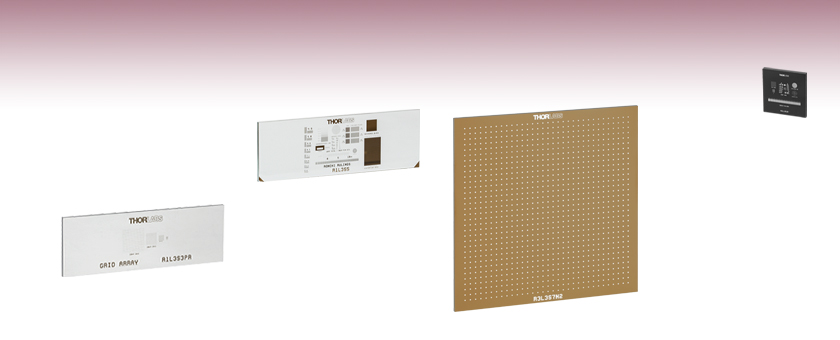

R1L3S5P

Combined Resolution and

Distortion Test Target

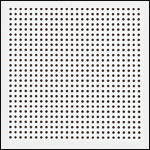

R1L3S3PR

Positive Reflective Grid

Distortion Target

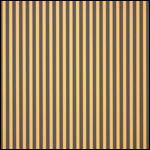

R3L3S7N2

Fixed Frequency Negative Grid

Distortion Target

R1L1S1N

Combined Resolution and

Distortion Test Target

Please Wait

| General Specifications | |

|---|---|

| Substrate | Sode Lime Glass |

| Substrate Thickness | 0.06" (1.5 mm) |

| Surface Flatness | ≤15 µm |

Click to Enlarge

An R1L3S5P Combined Resolution and Distortion Test Target Mounted in an XYF1 Test Target Positioner

Features

- Fixed and Multi-Frequency Grid Distortion Test Targets

- High-Contrast Positive Reflective Target Available

- Combined Resolution and Distortion Test Targets

- Distortion in Grid Image Allows for Image Correction

- Grids Available with Spacings of 2 µm to 5000 µm

Thorlabs offers a variety of options for measuring the distortion of an optical system including targets with a single-frequency grid, multi-frequency grids, or distortion grids alongside a wide variety of other patterns for resolution measurement, calibration, and more. Combined, these targets offer grid spacings ranging from 2 µm to 5000 µm.

A variety of targets are offered below, including positive and negative fixed-frequency grid distortion targets, multi-frequency grid distortion targets, single-frequency Ronchi ruling targets, concentric circle and crosshair grid targets, and combined resolution and distortion targets. We also offer a positive reflective version of the multi-frequency target and a negative version of the 18 mm x 18 mm combined resolution and distortion target. The targets below are made by plating vacuum-sputtered low-reflectivity chrome on a soda lime glass substrate in patterns of either horizontal and vertical lines or rows and columns of solid circles. See the Graphs tab for spectral data of the materials used in these distortion targets.

Each pattern is manufactured using photolithography, allowing for edge features to be resolved down to approximately 1 µm. Since the targets have parallel lines or perpendicular rows and columns, they will be imaged as such by an ideal system. A distorted image will show the lines or rows and columns as bowed; this image allows the user to quantify the distortion and thus to correct for it using software built into programs such as LabVIEW or ImageJ.

Mounting

These distortion test targets can be mounted in one of four of our microscopy slide holders. Our MAX3SLH fixed slide holder provides two spring clips to mount the optic and can be mounted to any of our 3-axis translation stages; this slide holder is only compatible with test targets greater than or equal to 2" wide and provides a clear aperture of 1", which may cover the chrome pattern on some of the test targets. Thorlabs also offers our XYF1(/M) test target positioning mount (see photo to the right), which is capable of translating a 1" (25.4) to 3" (76.2 mm) wide rectangular target over a 50 mm (1.97") x 30 mm (1.18") area. The mount offers five 8-32 (M4) taps for six post-mountable orientations. Please note that the mount's support arms overlap the optic by 4.4 mm on each side. Thorlabs' XF100(/M) can hold test targets from 12.7 mm to 126.2 mm (0.50" to 4.97") in width and provides translation with up to 100 mm of travel. The XYF1(/M) and XF100(/M) mounts use nylon-tipped setscrews to secure the optic. For users of our high-speed motorized XY scanning stages, we offer the MLS203P2 slide holder for inverted microscopes, which can mount slides that measure 25 mm to 26.5 mm in width and petri dishes that measure 30 mm to 60 mm in diameter.

| Targets Selection Guide | ||||

|---|---|---|---|---|

| Resolution Test Targets | Calibration Targets | Distortion Test Targets | Slant Edge MTF Target | Stage Micrometers |

Click to Enlarge

Soda Lime Glass Transmission

Click to Enlarge

Spectral Curves of Reflective Test Targets

The large difference between the chrome (blue line) and low-reflectivity chrome (red line) in the visible region means that the positive reflective targets have high contrast between the pattern and the background.

| Customization Parameters | ||

|---|---|---|

| Substrate Sizea | Min | 8 mm x 8 mm (5/16" x 5/16") |

| Max | 85 mm x 85 mm (3.35" x 3.35") | |

| Substrate Materials | Soda Lime Glass UV Fused Silica Quartz |

|

| Coating Material | Chromeb Low-Reflectivity Chromec |

|

| Coating Optical Density | ≥3d or ≥6e @ 430 nm | |

| Minimum Pinhole/Spot | Ø1 µm | |

| Minimum Line Width | 1 µm | |

| Line Width Tolerance | -0.25 / +0.50 µm | |

| Maximum Line Density | 500 lp/mm | |

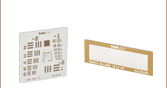

Custom OEM Test Targets and Reticles

Our in-house photolithographic design and production capabilities enable us to create a range of patterned optics. We manufacture test targets, distortion grids, and reticles at our Thorlabs Spectral Works facility in Columbia, South Carolina. These components have served a wide variety of applications, being implemented in microscopes, imaging systems, and optical alignment setups.

In addition to our catalog test targets and reticles offered from stock, we can provide custom chrome patterns on soda lime, UV fused silica, or quartz substrates from 8 mm by 8 mm up to 85 mm by 85 mm. Substrates can be cut to shape for your application. Our photolithographic coating process allows us to create chrome features down to 1 µm. A few sample patterns are shown below, which can be made positive or negative, as shown in the image directly below.

For a quote on custom test targets and reticles, please contact us at TSW@thorlabs.com.

Sample Patterns

Example Applications

- Etched Reticles

- Gray Scale Masks

- Resolution Reticles

- Diagnostic Reticles

- Recreational Scopes

- Notching Reticles

- Eyepiece Scales

- Illuminated Crosshairs

- Obstruction Targets

- Binocular Reticles

Click to Enlarge

Positive and Negative Crosshair Sample Pattern

This tab details an optimal cleaning technique developed by our engineers for cleaning reticles, test targets, distortion targets, and calibration targets.

Cleaning Procedure

- Use a clean wet sponge, preferably made of polyvinyl alcohol (PVA), and dish detergent to gently scrub the front and back surfaces of your reticle or target.

- Rinse with water.

- Blow dry with clean dry air, or allow the reticle or target to air dry on a clean surface.

We do not suggest using a towel, rag, or wipe to dry the surface. If contamination persists, soak the reticle or target in a detergent and water solution for 1 hour, repeating as necessary.

| Posted Comments: | |

Brian Matcheski

(posted 2024-11-28 09:17:19.97) Hello,

Are these slides traceable to a standard. i.e what certifications are available? thanks cdolbashian

(posted 2024-12-10 01:29:26.0) Thank you for reaching out to us with this request. We can indeed provide self-certification, verifying that the critical dimensions of the target fall within the values which we consider "within spec". In the case of the R1L3S3P, the centering tolerance will be +/-250nm and the dimensional tolerance will be +/-500nm for any given element on the target. I have reached out to you in order to discuss how we can facilitate your acquisition of this information. Preston Chang

(posted 2024-08-12 15:55:33.09) Hi Sir,

Could you provide a calibration report on R1L3S3P? cdolbashian

(posted 2024-08-14 11:48:50.0) Thank you for reaching out to us with this request. We can provide a certificate of conformance, ensuring that the target meets our dimensional specifications. I have contacted you directly to help you acquire such information. Marc Van Zadel

(posted 2022-11-21 09:37:07.017) Hello @ Thorlabs, it would be an improvement if there was an alignment line from one center grid to the center of the others.

That, or have all the grids aligned on the top.

Now it's hard at 64x or 100x to find the smaller grids without zooming out to 10x or 20x or so. cdolbashian

(posted 2022-11-22 03:52:00.0) Thank you for the suggestion! I have reached out to you to discuss this as a potential custom, as well as requesting such a product internally to be available for future customers. Tsong Lai

(posted 2021-07-05 16:12:35.863) Hi ThorLabs

We want to purchase the R1L3S3P.

If we place the order , how many days we can receive it if ship to Taiwan ?

Regards

Tsong YLohia

(posted 2021-07-07 02:58:48.0) Hello, thank you for contacting Thorlabs. Questions about shipping are answered by our Sales team (sales@thorlabs.com) / your local Thorlabs distributor. The amount of time depends on the shipping speed chosen at the time of your order. Konstantin Novoselov

(posted 2019-11-26 14:17:27.287) We need to produce optical calibration target to estimate/correct optical distortion in our instrument. This calibration target is similar your Grid Distortion Test Targets. In our case calibration pattern should be formed on the top of microscopic slide 25x50 mm 1.1 mm thickness. Calibration pattern consist of Ø150 µm dots arranged in a grid with spacing 200 µm.

Desired spacing and dot size tolerance is about 2-3 µm. Expected order quantity is 1-10 during prototyping stage and 100-1000 in production stage.

Can you please provide me with ballpark estimation of the manufacturing costs and lead times. llamb

(posted 2019-12-03 10:59:48.0) Thank you for contacting Thorlabs. For custom quotes, you may contact us at TechSupport@thorlabs.com by clicking the Request A Quote button above. I have reached out to you directly to discuss this particular case. dave.stubblefield

(posted 2017-02-23 07:04:15.327) Do you have any distortion targets that are designed for the IR spectrum? 3-5 micron and 8-12 micron. Maybe with a different substrate? Most transmission curves that I can find for soda lime glass do not extend into the IR region. tfrisch

(posted 2017-03-13 03:44:30.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly about our custom capabilities for etching distortion targets. |

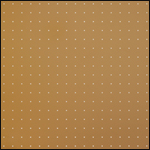

Click to Enlarge

An R2L2S3P3 Target Post Mounted via an FFM1 Filter Mount and a B3C Cube Base for Use in a Custom Imaging System

Click for Details

A Close Up of the Dot Pattern on the R2L2S3P4 Target

- One Grid Array on a 1.50" x 1.50" (38.1 mm x 38.1 mm) Soda Lime Glass Substrate

- 50 µm, 125 µm, 250 µm, 500 µm, or 1000 µm Grid Spacings

- Ø25 µm, Ø62.5 µm, Ø125 µm, Ø250 µm, or Ø500 µm Dots

- Ideal for Stage Calibration and Distortion Detection in Machine Vision Applications

These distortion grid arrays each feature a single grid of dots fabricated from the deposition of vacuum-sputtered, low-reflectivity chrome on a soda lime glass substrate. The available grid spacings, which are measured from the center of any dot to the center of any adjacent dot, range from 50 µm to 1000 µm, and the dot diameters range from 25 µm to 500 µm.

Grid arrays are used to determine the distortion of an imaging system. Ideally, the horizontal and vertical rows of dots should be perpendicular to each other. A distorted image will show the array as bowed; this image can then be used to correct for distortion.

| Item # | Spacinga | Spacing Tolerance |

Dot Size | Dot Size Tolerance |

Pattern | Background | Pattern Sizeb | Pattern Size Tolerance |

Pattern Optical Density |

Substrate Size |

|---|---|---|---|---|---|---|---|---|---|---|

| R2L2S3P5 | 50 µm | ±1 µm | Ø25 µm | ±2 µm | Low-Reflectivity Chrome |

Clear | 25.0 mm x 25.0 mm (0.98" x 0.98") |

±4 µm | ≥3.0 at 430 nm | 1.50" x 1.50" x 0.06" (38.1 mm x 38.1 mm x 1.5 mm) |

| R2L2S3P1 | 125 µm | Ø62.5 µm | ||||||||

| R2L2S3P2 | 250 µm | Ø125 µm | ||||||||

| R2L2S3P3 | 500 µm | Ø250 µm | 25.4 mm x 25.4 mm (1.00" x 1.00") |

|||||||

| R2L2S3P4 | 1000 µm | Ø500 µm |

Click for Details

A Close Up of the Dot Pattern on the R3L3S7N1 Target

- One Grid Array on a 90 mm x 90 mm (3.54" x 3.54") Soda Lime Glass Substrate

- 2500 µm or 5000 µm Grid Spacings

- Ø500 µm Dots

- Ideal for Machine Vision Applications of Stage Calibration and Distortion Detection

These distortion grid arrays each feature a single grid of dots fabricated from the deposition of vacuum-sputtered, low-reflectivity chrome on a soda lime glass substrate. Grid spacings of 2500 µm or 5000 µm are available and are measured from the center of any dot to the center of any adjacent dot. The dot diameter is 500 µm.

Grid arrays are used to determine the distortion of an imaging system. Ideally, the horizontal and vertical rows of dots should be perpendicular to each other. A distorted image will show the array as bowed; this image can then be used to correct for distortion.

| Item # | Spacinga | Spacing Tolerance |

Dot Size | Dot Size Tolerance |

Pattern | Background | Pattern Sizeb | Pattern Size Tolerance |

Pattern Optical Density |

Substrate Size |

|---|---|---|---|---|---|---|---|---|---|---|

| R3L3S7N2 | 2500 µm | ±5 µm | Ø500 µm | ±5 µm | Clear | Low-Reflectivity Chrome |

80.0 mm x 80.0 mm (3.15" x 3.15") |

±5 µm | ≥3.0 at 430 nm | 90.0 mm x 90.0 mm x 1.5 mm (3.54" x 3.54" x 0.06") |

| R3L3S7N1 | 5000 µm |

| Optical Specifications | |||

|---|---|---|---|

| Item # | R1L3S3P1 | R1L3S3P | R1L3S3PR |

| Pattern | LRa Chrome | LRa Chrome | LRa Chrome |

| Background | Clear | Clear | Chrome |

| Chrome Optical Densitya | ≥3.0 | ≥3.0 | - |

| Reflectanceb | - | - | LRa Chrome: <10% Chrome: >40% |

- Four or Five Grid Arrays on a 3.00" x 1.00" (76.2 mm x 25.4 mm) Soda Lime Glass Slide

- 5 µm, 10 µm, 50 µm, 100 µm, and 500 µm Grid Spacings

- Ideal for Stage Calibration and Distortion Detection in Microscopy Applications

- Same Outer Dimensions as a Standard Microscope Slide

- High Contrast Positive Reflective Target Available

These grid distortion targets feature four or five arrays of horizontal and vertical lines spaced 5 µm, 10 µm, 50 µm, 100 µm, or 500 µm apart. This pattern is fabricated from the deposition of low-reflectivity, vacuum-sputtered chrome on a 3.00" x 1.00" x 0.06" (76.2 mm x 25.4 mm x 1.5 mm) soda lime glass substrate. The dimensions of the glass substrate are the same as a standard microscope slide.

The R1L3S3P1 and R1L3S3P positive targets have a clear soda lime substrate background for front-lit and general applications, while the R1L3S3PR positive reflective target has a chrome background for high contrast in reflective applications. See the Graphs tab for details.

Grid arrays are used to determine the distortion of an imaging system. Ideally, the horizontal and vertical lines of the grid should be perpendicular to each other. A distorted image will show the lines as bowed; this image can then be used to correct for distortion.

Click to Enlarge

Close Up of R1L3S14N Ronchi Ruling Pattern

| Optical Specifications | |

|---|---|

| Pattern | Alternating Clear and LRa Chrome Lines |

| Background | LR Chrome |

| Chrome Optical Densityb | ≥3.0 |

- 3.00" x 1.00" (76.2 mm x 25.4 mm) Square Wave Ronchi Ruling Target

- Patterns with Spacings from 0.5 lp/mm to 500 lp/mm

- Large 65 mm x 17 mm Clear Aperture

- Determine Resolution, Field Distortion, and Parfocal Stability in an Optical System

- Low-Reflectivity, Vacuum-Sputtered Chrome on Soda Lime Glass

- Compatible with our MLS203 Microscope Stages via MLS203P2 Slide Holder

Thorlabs offers Ronchi ruling targets with resolutions ranging from 0.5 line pairs per millimeter (lp/mm) to 500 lp/mm, where a line pair is one light line and one dark line. These square wave, constant-interval bar and space patterns are fabricated from the deposition of a dark low-reflectivity chrome pattern on a 3.00" x 1.00" x 0.06" (76.2 mm x 25.4 mm x 1.5 mm) soda lime glass substrate. This leaves a large 65 mm x 17 mm clear aperture and works well in back-lit and highly illuminated applications. The dimensions of the glass substrate are the same as a standard microscope slide. These Ronchi rulings are excellent for evaluating resolution, field distortion, and parfocal stability in optical systems.

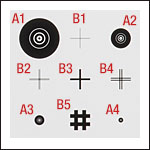

Click to Enlarge

Close Up of the Smaller Grid on the R3L3S5P Target with Labels Added (See Tables Below)

Click to Enlarge

Close Up of Entire Pattern on the R3L3S5P Target

| Optical Specifications | |

|---|---|

| Pattern | LRa Chrome |

| Background | Clear |

| Chrome Optical Densityb | ≥3.0 |

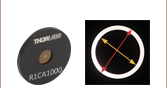

- Concentric Circles and Crosshair Patterns Arranged in a Grid

- Four Different Concentric Circle Sizes and Five Different Crosshair Sizes

- Measure Resolution and Distortion of an Imaging System

- 3.00" x 3.00" (76.2 mm x 76.2 mm) Soda Lime Glass Substrate

Thorlabs' 3.00" x 3.00" (76.2 mm x 76.2 mm) Concentric Circle and Crosshair Grid Target offers 289 individual grids, arranged in a larger, 2" x 2" grid of 17 rows and 17 columns. The smaller grids each have four concentric circle patterns and five crosshair patterns of varying sizes. The concentric circle and crosshair patterns on the smaller grids are labeled in the image to the right but not on the target itself. Each concentric circle pattern features seven different radii, while the crosshairs each have a single or a double cross. For details on the dimensions of these patterns, see the tables below.

The pattern on this target is made by plating low-reflectivity, vacuum-sputtered chrome on a 0.06" (1.5 mm) thick soda lime glass substrate to achieve an optical density of ≥3.0 at 430 nm. The dark pattern and clear substrate are useful for front-lit and general applications.

| Concentric Circles | |||||||

|---|---|---|---|---|---|---|---|

| Circle Patterna | R1 | R2 | R3 | R4 | R5 | R6 | R7 |

| A1 | 31.3 µm | 62.5 µm | 125 µm | 140.6 µm | 234.4 µm | 242.2 µm | 500 µm |

| A2 | 15.6 µm | 31.3 µm | 62.5 µm | 70.3 µm | 117.2 µm | 121.1 µm | 250 µm |

| A3 | 7.8 µm | 15.6 µm | 31.3 µm | 35.2 µm | 58.6 µm | 60.5 µm | 125 µm |

| A4 | 3.9 µm | 7.8 µm | 15.6 µm | 17.6 µm | 29.3 µm | 30.3 µm | 62.5 µm |

| Crosshairs | |||

|---|---|---|---|

| Crosshair Patterna | Single or Double Line | Length/Width | Line Widthb |

| B1 | Double | 500 µm | 6.25 µm |

| B2 | Double | 500 µm | 12.5 µm |

| B3 | Single | 500 µm | 50 µm |

| B4 | Double | 500 µm | 25 µm |

| B5 | Double | 500 µm | 100 µm |

Click to Enlarge

Microscope Image of the R1S1L1N Negative Test Target

| Optical Specifications | ||

|---|---|---|

| Item # | R1L1S1P | R1L1S1N |

| Pattern | LRa Chrome | Clear |

| Background | Clear | LRa Chrome |

| Chrome Optical Densityb | ≥3.0 | |

- Determine Resolution of an Optical System

- Measure Image Distortion, Astigmatism, and Other Aberrations

- 18.0 mm (0.71") Square, 1.5 mm (0.06") Thick Soda Lime Substrate

- Includes 1951 USAF Pattern, Sector Star, Concentric Circles, Grids, and Ronchi Rulings

- Positive and Negative Targets Available

Thorlabs offers positive and negative 18.0 mm x 18.0 mm x 1.5 mm combined resolution / distortion test targets that are made by plating low-reflectivity, vacuum-sputtered chrome with an optical density (OD) of ≥3.0 at 430 nm on a soda lime glass substrate. They are ideal for the calibration of imaging systems and microscope stages.

The test targets include a 1951 USAF pattern (Groups 2 - 7), a sector star, concentric circles, grids (100 µm, 50 µm, and 10 µm), and Ronchi rulings (30 - 150 lp/mm). These targets are useful for testing resolution, field distortion, focus errors, and astigmatism. The 1951 USAF targets are useful for measuring imaging resolution. The grids can be used to measure image distortion, while the concentric circles are ideal for identifying focus errors, astigmatism, and other aberrations existing in an imaging system. The Ronchi rulings are excellent for evaluating resolution, field distortion, and parfocal stability. For more information, please see our Resolution Targets page.

These resolution targets are offered in positive and negative versions. The R1L1S1P positive target consists of a low-reflectivity chrome pattern plated on to a clear substrate and is useful for front-lit and general applications. Alternatively, the R1L1S1N negative target uses the same low-reflectivity chrome coating to cover the substrate, leaving the pattern itself clear, and works well in back-lit and highly illuminated applications.

| Target Feature | Details | Target Feature | Details |

|---|---|---|---|

| 1951 USAF Target | Groups 2 - 7 | Concentric Circles | 10 Circles with Radii from 100 µm to 1000 µm in 100 µm Intervals, Labeled 1 to 10 |

| Grids | 20 x 20 Arrays with 100 µm, 50 µm, and 10 µm Pitch | Ronchi Rulings | 13 Rulings from 30 lp/mma to 150 lp/mm in 10 lp/mm Intervals |

| Sector Star | 36 Bars through 360°, 10 µm Radius Center Circle, and Ten Concentric Circles with Radii from 50 µm to 500 µm in 50 µm Intervals | ||

|

|

| Optical Specifications | |

|---|---|

| Pattern | LRa Chrome |

| Background | Clear |

| Chrome Optical Densityb | ≥3.0 |

- 3.00" x 1.00" (76.2 mm x 25.4 mm) Soda Lime Substrate

- Includes NBS 1963A Pattern, Sector Star, Concentric Circles, Grids, Ronchi Rulings, and More (See Table Below)

- Determine Resolution of an Optical System

- Measure Image Distortion, Astigmatism, and Other Aberrations

- Compatible with our MLS203 Microscope Stages via MLS203P2 Slide Holder

Thorlabs offers positive 3.00" x 1.00" x 0.06" (76.2 mm x 25.4 mm x 1.5 mm) combined resolution / distortion test targets that are made by plating vacuum-sputtered low-reflectivity chrome with an optical density (OD) of ≥3.0 at 430 nm on a soda lime glass substrate. They are ideal for the calibration of imaging systems and microscope stages. They are sized to fit in our MLS203P2 stage slide holder for use with our MLS203 microscope stages.

The test targets include an NBS 1963A pattern, a sector (Siemens) star, concentric circles, grids, Ronchi rulings, and more (see table below). These targets are useful for testing resolution, field distortion, focus errors, and astigmatism. The NBS 1963A, sector star, and concentric circle targets are useful for measuring imaging resolution. The grids can be used to measure the distortion introduced by an imaging system. The Ronchi rulings are excellent for evaluating resolution, field distortion, and parfocal stability. For more information, please see our Resolution Targets page.

| Target Feature | Details | Target Feature | Details |

|---|---|---|---|

| NBS 1963A | Frequencies from 4.5 cycles/mm to 228 cycles/mm (See List Above) | Concentric Circles | 10 Circles with Radii from 100 µm to 1000 µm in 100 µm Intervals |

| Distortion Grid (Squares) | 3 Grids: 100 lp/mma, 150 lp/mm, 200 lp/mm | Fixed Ronchi Rulings | 3 Rulings:100 lp/mm, 150 lp/mm, and 200 lp/mm |

| Distortion Grid (Dots) | 3 Grids: 400 µm Pitch of Ø80 µm Dots, 200 µm Pitch of Ø 40 µm Dots, 100 µm Pitch of Ø20 µm Dots |

Variable Ronchi Rulings | 20 Rulings (Each 1 mm x 1 mm): 10 lp/mm to 200 lp/mm in 10 lp/mm Intervals |

| Two-Point Resolution Dots | Ø25 µm, Ø20 µm, Ø15 µm, Ø12.5 µm, Ø10 µm, Ø7.5 µm, and Ø5 µm | Pinholes | Ø25 µm, Ø20 µm, Ø15 µm, Ø12.5 µm, Ø10 µm, Ø7.5 µm, and Ø5 µm |

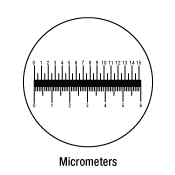

| Interdigitated Lines | 6.25 lp/mm, 12.5 lp/mm, 25 lp/mm, 50 lp/mm, 100 lp/mm, and 200 lp/mm | Micrometers | 3 Rulers: 10 mm Scale with 50 µm Divs, 1 mm Scale with 10 µm Divs, and 1mm x 1 mm XY Scale with 50 µm Divs |

| Sector Star | 36 Bars through 360°, 50 µm Radius Center Circle, and Ten Concentric Circles with Radii from 100 µm to 500 µm in 50 µm Intervals | ||

Products Home

Products Home

Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge Click to Enlarge

Click to Enlarge

Zoom

Zoom

Distortion Test Targets

Distortion Test Targets