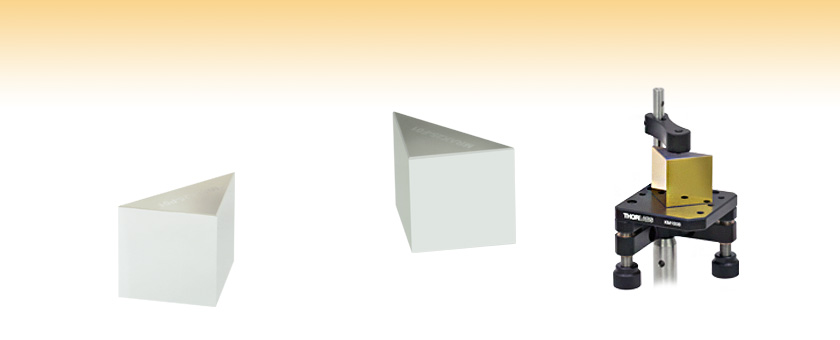

Knife-Edge Right-Angle Prism Mirrors

- Precision Cut Prisms Feature Bevel-Free 90° Angle

- Silver, Gold, and Aluminum Coatings Available

- 25 mm x 25 mm Faces

MRAK25-P01

MRAK25-F01

Application Idea

MRAK25-M01 Mounted

on a KM100B Kinematic

Platform Mount

Please Wait

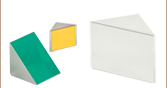

Figure 1.2 The size of these prisms is defined by the leg dimension, L. See the Specs tab for full product dimensions.

Click to Enlarge

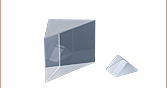

Figure 1.1 This schematic shows how two beams can be made collinear using these knife-edge right-angle prism mirrors.

Features

- Right-Angle Prism with Mirror-Coated Legs

- "Knife Edge" Between the Two Coated Surfaces for Combining or Separating Beams

- 25 mm x 25 mm Reflective Surfaces

Thorlabs' Knife-Edge Right-Angle Prism Mirrors feature reflective coatings on the two legs and offer a clear aperture extending across the 90° angle between the coated surfaces. They are manufactured from N-BK7 and have 25 mm x 25 mm reflective legs. These prism mirrors are offered with one of the following reflective coatings: UV enhanced aluminum, protected aluminum, protected gold, or protected silver. Please see the Specs and Graphs tabs for details on the reflectivity of the various coatings.

The precision corner between the two coated surfaces allows two counterpropagating beams to be made collinear with the output orthogonal to the input, as shown in Figure 1.1. They can also be used to split a single input beam aimed directly at the knife edge. The prisms are ideal for situations where it is undesirable to use a beamsplitting cube, such as due to the geometry of the setup. Some diffraction and scatter will occur whenever a beam is split using these prisms.

These prisms feature a coating that extends to the edge of the optic. Care should be used when handling the prisms, as the coated edge is very delicate and can be chipped easily.

While the hypotenuse is polished, these mirrors are not intended for use as retroreflectors due to the adhesion layers used in the coating process. As a result, no specifications are given for the polished hypotenuse of the prism. For retroreflection applications we suggest the PS911K, an uncoated version of our knife edge prism, or our selection of mounted and unmounted retroreflectors. Thorlabs also offers a selection of hypotenuse-coated right-angle prism mirrors.

| Right-Angle Prism Mirror Selection Guide |

|---|

| Hypotenuse Coated |

| Metallic Coatings (250 nm - 20 µm) |

| Dielectric Coatings (400 nm - 1100 nm) |

| Laser Line (532 nm and 1064 nm) |

| Leg Coated |

| Knife-Edge, Metallic and Dielectric Coatings (250 nm - 20 µm) |

| Dielectric Coating (750 nm - 1100 nm) |

Care and Handling

Silver coated mirrors require additional care due to their susceptibility to damage from environmental conditions and improper handling. Fingerprints, contact with abrasive surfaces, and environments with high humidity or temperature will diminish the effectiveness of the protective overcoat leaving the silver coating susceptible to oxidation and degradation. When working with silver mirrors, follow standard practices for handling optics. Latex gloves or similar protective coverings are recommended to prevent oil and other residues on the user’s fingers from reaching the optical surface. Even with such precautions, care should be taken not to touch the mirrored face or edges. Silver mirrors should be used and stored in areas at room temperature with minimal humidity. For information on how to clean mirrors and other optics, visit our Optic Cleaning Tutorial.

| Item # | MRAK25-F01 | MRAK25-G01 | MRAK25-P01 | MRAK25-M01 | |

|---|---|---|---|---|---|

| Coating (On Legs) | UV Enhanced Aluminum | Protected Aluminum | Protected Silver | Protected Gold | |

| Reflectancea | Ravg > 90% (250 -450 nm) | Ravg > 90% (450 - 2000 nm) Ravg > 95% (2 - 20 µm) |

Ravg > 97% (450 - 2000 nm) Ravg > 95% (2 - 20 µm) |

Ravg > 96% (800 nm - 20 µm) | |

| Substrate Material | N-BK7 | ||||

| Lb | 25.0 mm | ||||

| Xb | 35.4 mm | ||||

| Clear Aperture (Coated Surfaces) |

Entire Face Length and Width, Excluding a 1.25 mm Border Along All Beveled Edges | ||||

| Clear Aperture (Hypotenuse) |

90% of Face Length and Width | ||||

| Surface Flatness (All Surfaces) |

λ/8 @ 632.8 nm Over the Clear Aperture (Peak to Valley) | ||||

| Surface Quality | 20-10 Scratch-Dig | ||||

Figure 2.1 Right-Angle Prism Dimensions

Figure 2.1 Right-Angle Prism Dimensions Figure 2.2 Right-Angle Prism Diagram

Figure 2.2 Right-Angle Prism DiagramAll data shown below is for unpolarized light, unless otherwise stated. The shaded regions in the graphs denote the ranges over which we guarantee the specified reflectance. Please note that the reflectance outside of these bands is typical and can vary from lot to lot, especially in out-of-band regions where the reflectance is fluctuating or sloped.

UV-Enhanced Aluminum Coating (250 - 450 nm)

Protected Aluminum Coating (450 nm - 20 µm)

Protected Silver Coating (450 nm - 20 µm)

Protected Gold Coating (800 nm - 20 µm)

| Posted Comments: | |

Peter Domenicali

(posted 2025-02-24 08:42:31.04) Several previous customers have inquired about the sharpness of the knife edge. The most recent answer was that you expect it to be less than 100 um. Short of us buying one and examining it under a microscope, can you please advise whether the maximum width of the edge break might be less than 20 um? That is our present requirement for such a component, so we need to know whether this part will meet our needs. Bram Verreussel

(posted 2024-10-15 08:25:10.05) What coating is used for the MRAK25 prisms? Specifically the P01 and M01 prisms. The coatings seem to be degraded after 8 years but it's hard to tell what's happening without knowing what the coating is made of. jpolaris

(posted 2024-10-18 07:47:28.0) Thank you for contacting Thorlabs. The MRAK25-P01 and MRAK25-M01 knife-edge right-angle prism mirrors are coated with our 'protected silver' and 'protected gold' coatings, respectively. A page detailing these two coatings, as well as our other metallic and dielectric coatings, can be found at the following link. "Protected" in these two cases refers to the fact that these coatings have an SiO2 overcoat, which helps prevent damage from scratching and smudging, and delays corrosion/ oxidization. I have reached out to you directly to discuss the environmental conditions your prisms were used and stored in. Aside from environmental conditions, damage can occur optically. I have included laser-induced damage thresholds for the -P01 and -M01 coatings in my email to you. https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=5840&tabname=HR_Coating Will Christopherson

(posted 2024-03-26 16:57:20.8) I would also like to understand current measurements on the knife edge sharpness. Specifically my use would be to position the edge to split imaged spots separated by ~100 um. Thanks! jdelia

(posted 2024-04-18 08:49:41.0) Thank you for contacting Thorlabs. We do not explicitly characterize the sharpness of the edge, but based on our measurements and testing procedures, we would expect the edge to be sharper than 100um. user

(posted 2023-11-06 17:11:39.37) What is the dead zone "thickness" of the knife edge ? cdolbashian

(posted 2023-11-15 09:46:55.0) Thank you for reaching out to us with this inquiry. On the product page we state the following "These prisms feature a coating that extends to the edge of the optic", indicating that there is no "dead zone" on the optic. I have reached out to you directly to discuss this, in the case where I am misunderstanding your inquiry. RAMPRAKASH ANANTHAPADMANABAN

(posted 2023-09-28 02:21:57.04) Hi,

I have two laser beams that are 10 mm apart. Can I use MRAK25-P01 to redirect it perpendicular to the incoming direction? jpolaris

(posted 2023-09-28 05:13:53.0) Thank you for contacting Thorlabs. Yes, our Knife-Edge Right-Angle Prism Mirrors, such as MRAK25-P01, can be used to redirect parallel beams into opposite perpendicular directions. The coated faces of MRAK25-P01 have side lengths of 25 mm, so there would be no issues from your 10 mm beam spacing. Yuqin Yan

(posted 2023-03-15 19:39:07.857) MRAK25-E03 jdelia

(posted 2023-03-23 09:34:34.0) Thank you for contacting Thorlabs. I have reached out to you directly to clarify what your question regarding MRAK25-E03, and also discuss some alternative options to this obsolete part. Daniel Dickinson

(posted 2021-04-26 08:54:08.217) I noted from previous comments that you are able to offer these prisms with dielectric coatings. Can you please reach out to me with a quote for the E02 coating?

I was also curious if it's possible to make these prisms with a higher surface flatness, similar to your BB1 mirrors (lambda/10). YLohia

(posted 2021-04-26 01:55:37.0) Thank you for contacting Thorlabs. Custom optics can be requested by emailing techsupport@thorlabs.com. We will reach out to you to discuss the possibility of offering this customization. Lorenz Sykora

(posted 2020-07-23 12:28:32.3) Is ist possible to get it also with unprotected gold. We are working in the midinfrared region and the absorption of the protected gold for 45° is way to much. 45° would be the standard angle for this optical component. YLohia

(posted 2020-07-23 02:39:03.0) Thank you for contacting Thorlabs. Custom optics can be requested by emailing techsupport@thorlabs.com. We will reach out to you to discuss the possibility of offering this customization. Marshall Scott

(posted 2019-10-21 14:37:34.193) rstahl (posted 2018-05-01 14:47:00.51)

How sharp is the knife edge? How small a beam diameter could I split with this part?

YLohia (posted 2018-05-02 10:31:35.0)

Hello, unfortunately, we do not specify an exact thickness of the knife edge on these prisms; we design the thickness of the edge as thin as our manufacturing abilities allow and is suited for general beamsplitting and beam combining applications.

:( YLohia

(posted 2019-11-05 03:15:05.0) We specify no chamfer on this surface to ensure working distance is available as close to the edge as possible. We are currently working on defining a specification as to how sharp that edge actually is. I will reach out to you via e-mail to discuss this further. lebouquj

(posted 2018-06-07 16:32:10.937) Hello, Could you offer MRAK20-M01, that is with 20mm legs instead of 25mm ? Thanks, Jean-Baptiste nbayconich

(posted 2018-06-12 10:15:57.0) Thank you for contacting Thorlabs. We can look into providing this custom for you. I will reach out to you directly with more information.

For any custom requests please contact techsupport@thorlabs.com directly. simon.neves

(posted 2018-05-03 17:13:22.78) Dear Sir/Madam,

Do you provide a knife edge with dielectric coatic for 1550 nm wavelength ?

Thank you for your help

Simon Neves YLohia

(posted 2018-05-04 10:02:31.0) Dear Simon, thank you for contacting Thorlabs. We do have the ability to provide these knife-edge right-angle prisms with our selection of dielectric coatings as specials. We will contact you directly for more details. rstahl

(posted 2018-05-01 14:47:00.51) How sharp is the knife edge? How small a beam diameter could I split with this part? YLohia

(posted 2018-05-02 10:31:35.0) Hello, unfortunately, we do not specify an exact thickness of the knife edge on these prisms; we design the thickness of the edge as thin as our manufacturing abilities allow and is suited for general beamsplitting and beam combining applications. pierrick.cheiney

(posted 2018-04-17 15:59:01.933) Dear Sir/Madam,

Could you provide knife-edge prism mirror in smaller size such as 5 or 10 mm width?

Best regards,

Pierrick Cheiney YLohia

(posted 2018-04-17 11:17:46.0) Hello Pierrick, thank you for contacting Thorlabs. We will reach out to you directly to discuss the possibility of offering this. yitzhak.malka

(posted 2018-01-31 08:59:18.217) Can you please indicate the 90degree angle accuracy? nbayconich

(posted 2018-02-07 04:19:12.0) Thank you for contacting Thorlabs. The tolerance to the 90 degree angle is ±3 arcminutes. cmullark

(posted 2018-01-18 05:27:01.987) I have a question:

What is the thickness of the knife-edge? If I place the prism in the focal plane of a beam to split it than as I focus tighter and tighter there will be more scattering/loss determined primarily by the knife edge thickness. Would it be different between the dielectric coating and the protected silver?

Thanks for any help you can provide in this matter. nbayconich

(posted 2018-03-30 04:25:50.0) Thank you for contacting Thorlabs. We do not specify an exact thickness for either coating type of these knife edge prisms, we design the thickness of the edge as thin as our manufacturing abilities allow. |

Products Home

Products Home

Knife-Edge Right-Angle Prism Mirrors

Knife-Edge Right-Angle Prism Mirrors