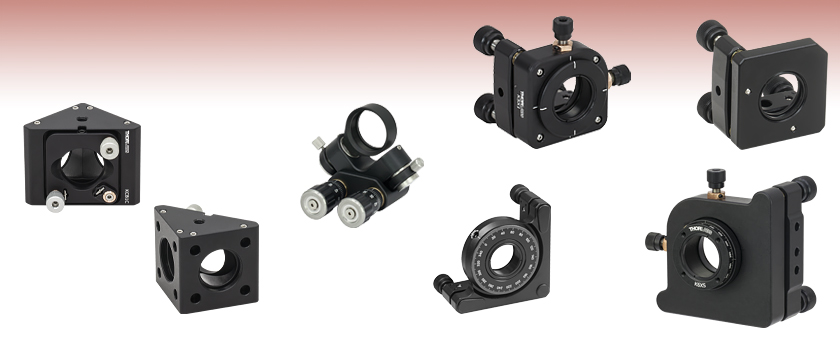

SM1-Compatible Kinematic and Gimbal Mounts

- SM1 (1.035"-40) Threading

- Mount SM1 Lens Tubes

- Mount Ø1/2" Parabolic or Ø1" Circular, Elliptical, or Parabolic Optics

Back

Front

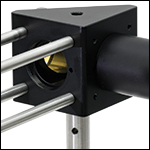

KCB1C

30 mm Cage Right-Angle Kinematic Mirror Mount with Smooth Cage Rod Bores

K5X1

5-Axis Kinematic Optic Mount

GMB1

Full Gimbal Mirror Mount for Ø1" Optics

KS1T

Ø1" Kinematic Mount for Optics up to 0.14" (3.5 mm) Thick, 3 Adjusters

K6XS

6-Axis Kinematic Optic Mount

KS1RS

Ø1" Kinematic Rotation Mount

Please Wait

Features

- Fine Adjustment Actuators for Precise Positioning

- SM1-Threaded Kinematic and Gimbal Mounts Available

- Mount Ø1/2" Parabolic or Ø1" (25.4 mm) Round, Elliptical, or Parabolic Optics

- Integrate SM1-Threaded Components such as Lens Tubes, Irises and Adapters

These SM1-threaded (1.035"-40) mounts allow a variety of optical components to be integrated into optomechanical setups. All of these kinematic and gimbal mounts allow for versatility and flexibility in optomechanical constructions due to compatibility with SM1-threaded lens tubes, irises, and adapters. In addition, these mounts (except for the KC45D1 cage assembly mount) all include tapped holes or counterbores for post mounting (see below for details).

Kinematic Mounts offer pitch and yaw movement and precise angular adjustment. Gimbal mounts offer rotational movement without angular or positional crosstalk. The KS1RS and K6XS provide continuous 360° rotational adjustment and ±4° kinematic tip/tilt adjustment, while the K5X1 and KC5X1(/M) offer tip, tilt, and x, y, z translation. The KC5X1(/M), KC1T(/M), KCB1, KCB1C, KCB1E, KCB1EC, KCB1P5(/M), KCB1P(/M), and the KC45D1 mounts are not only SM1-compatible, but also 30 mm cage system compatible.

This page contains our SM1-Compatible Kinematic and Gimbal Mounts; for a full selection of available kinematic mounts, please visit our Kinematic Mounts and Mirror Mounts navigation menus.

| Table 122E SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| Table 122F RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| Table 122G C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| Table 122H SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| Table 122J SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| Table 122K SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| Table 122L SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| Table 122M SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| Table 122N SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

| No Comments Posted |

Click to Enlarge

Figure 238C In this image, the KM100T is mounted with one of two back-located #8 (M4) counterbores, which are orthogonal to the optic mounting bore and to each other. Both Figures 238B and 238C show the F280APC-B fiber collimator mounted in the KM100T kinematic mount using an AD11F adapter.

Click to Enlarge

Figure 238B In this image, the KM100T is mounted upwards using the #8 (M4) counterbore accessed by a through hole in the front plate.

Click to Enlarge

Figure 238A Mirror Surface Aligned Over the Post Axis Using Our

KMCP Centering Plate

- SM1-Threaded Optic Cell Uses Two Retaining Rings to Secure Ø1" Optics Up to 0.14" (3.5 mm) Thick

- Angular Range: ±4°

- Resolution: 8 mrad (0.5°) per Revolution via Two 1/4"-80 Adjusters

- Three Counterbored #8 (M4) Through Holes Allow for Left-Handed, Right-Handed, or Upward-Facing Orientation

- Ø1" Lens Tube Compatible via SM1 Threading

The KM100T SM1-Threaded Kinematic Mirror Mount is designed for use with thin Ø1" optics up to 0.14" (3.5 mm) thick. An optic is secured in the mounting hole with the two included SM1RR SM1 (1.035"-40) threaded retaining rings, which can be attached using the SPW602 spanner wrench. This mount is also compatible with SM1-threaded components, including our Ø1" lens tubes.

The KM100T mount is compatible with both imperial and metric threaded Ø1/2" mounting posts via #8 (M4) counterbored through holes, and can be attached to the post in a right-handed, left-handed, or upward-facing orientation, as shown in Figures 238A, 238B, and 238C. The two 1/4"-80 actuators utilize a 5/64" (2.0 mm) hex socket that is accessible with or without knobs removed. An optional accessory, the LN2580 bronze locking nut, is available to lock the adjusters once the desired position is reached. The KMCP(/M) adapter can also be used to center the KM100T mount over the center of a post.

SM-threaded kinematic mounts are also suitable for mounting cylindrical components such as fiber collimators using adapters such as the AD11F, as shown in Figures 238B and 238C.

- Internally SM1-Threaded (1.035"-40) for Ø1" Lens Tube Compatibility

- Mounts Thin Ø1" Optics up to 0.14" (3.6 mm) Thick via Included Retaining Rings

- Two Counterbored #8 (M4) Through Holes Allow for Left-Handed or Right-Handed Orientation

- Angular Range: ±4°

- Three lockable 1/4"-80 Precision Adjusters Provide 8 mrad (0.5°) of Travel per Revolution

- Removable Knobs Expose Hex Sockets in the Adjuster Screws

The KS1T mirror mount uses a retaining ring for stress-free mounting of a thin optical component. An optic is secured in the mounting hole with the two included SM1RR SM1 (1.035"-40) threaded retaining rings, which can be attached using the SPW606 spanner wrench. This threading also allows the mount to be compatible with Ø1" lens tubes. This mount incorporates a thicker back plate than our two adjuster mirror mount, sold above, thereby providing increased stability. In addition to the increased mass of the mount, stiffer springs and hardened inserts at all contact points have been utilized to enhance the overall performance.

The KS1T is universal, making it compatible with both imperial and metric threaded Ø1/2" mounting posts via a #8 (M4) counterbored through hole, and can be attached to the post in a right-handed or left-handed orientation. The mount has removable knobs that expose hex sockets in the lead adjuster screws. The KS1T features three 1/4"-80 TPI, lockable adjusters that allow the ±4° adjustment range to be altered by translating the front plate of the mirror mount. The spacing between the front and back plate must be 0.120" (3.05 mm) for the adjustment range to be symmetric (i.e., ±4°). When using all three adjusters, a maximum Z translation of 0.25" (6.4 mm) can be achieved.

As shown in Figure G2.1, the internal threads can also be used to mount externally threaded adapters, allowing for various components to be mounted such as laser diode modules or fiber collimators.

Click to Enlarge

Figure 418A KC1T Back View

- ±5º Tip / Tilt, ±3 mm Linear Translation Along the Optical Axis

- Accepts Ø1" (25.4 mm) Optics

- Maximum Optic Thickness: 0.23" (5.8 mm)

- Compatible with 30 mm Cage System

- 8-32 (M4 x 0.7) Holes for Post Mounting on Three Sides

The KC1T(/M) Kinematic Mount is designed with an SM1-threaded (1.035"-40) mounting hole that can directly hold optics up to 5.8 mm (0.23") thick using the two included SM1RR Retaining Rings. Thicker optics can be accommodated by housing the optic in one of our SM1-Series Lens Tubes and then threading the lens tube into the front plate of the mount. Alternatively, since the back plate features an oversized Ø1.32" bore, SM1 lens tubes can also be attached to the front plate from the rear of the mount without sacrificing angular adjustment. This kinematic mount comes with three 1/4"-80 adjusters that provide 0.4° (7 mrad) adjustment per revolution and up to ±5° of tip and tilt without cage rods inserted through the mount. Each of the mount's three adjusters can be independently locked using a side-located 5/64" (2.0 mm) hex setscrew.

Both the front and rear plate have been machined with four clearance holes designed for direct compatibility with our 30 mm cage system standard. The cage rod holes in the front plate are sufficiently oversized to allow ±4° tip and tilt adjustment without cage rod interference. Once the mount has been slid along the cage rods to the desired position, tighten the 5/64" (2.0 mm) locking setscrews on the back plate to secure it in place. The back plate also has 8-32 (M4 x 0.7) mounting holes on three of the four sides, providing compatibility with Thorlabs' Ø1" mounting posts.

- Combines Kinematic Angular Adjustment with Rotation in One Mount

- Three 1/4"-80 Lockable Stainless Steel Adjusters with Removable Knobs and Brass Bushings for Smooth Adjustments

- Six #8 (M4) Counterbored Mounting Holes Allow Left-Handed or Right-Handed Orientations

- Engraved Rotation Scale with 2° Graduations Provides 360° Rotation

- SM1-Threaded (1.035"-40) Rotation Ring with Locking Screw

The KS1RS is designed to hold Ø1" (25.4 mm) optics in situations where it is necessary to control the tip/tilt position as well as the rotation of the optic. This mount is ideal for polarization optics such as linear polarizers or wave plates. In addition, our Ø1" round cylindrical lenses may also be mounted in the KS1RS when it is necessary to adjust the angle of the line produced at the focal plane. The KS1RS features an SM1-threaded bore capable of mounting Ø1" optics up to 0.47" (11.9 mm) thick using the included SM1RR retaining ring. Additionally, SM1 lens tubes may be threaded onto the mount to accommodate thicker optics.

Thorlabs' Kinematic Rotation Mounts combine the features of our Precision Kinematic Mirror Mounts and Manual Rotation Mounts, providing continuous 360° rotational adjustment and ±4° kinematic tip/tilt adjustment. These mounts are therefore ideal for holding optics with rotational

The rotation of the mount may be locked in position with a locking screw. The locking screw is activated using a 5/64" (2 mm) hex key. The kinematic adjustment is provided by three 1/4"-80 adjusters with brass bushings to provide smooth adjustment. Each adjuster may be locked with a locking screw using a 5/64" (2 mm) hex key.

Please note that while this mount is designed to hold Ø1" optics, the mount uses the same form factor as the KS2 Ø2" mirror mount in order to incorporate the rotation ring.

If higher adjustment resolution or control is desired, the 1/4"-80 adjusters used in these mounts can be switched with DAS110 or DM22 Differential Adjusters.

- Five Axes of Adjustment with Locks:

- Kinematic Pitch/Yaw: ±4° with 8 mrad/rev

- X and Y Translation: ±1.0 mm with 254 µm/rev

- Z Translationa: ±0.13" (±3.2 mm) with 318 µm/rev

- SM1-Threaded Bore for Ø1" (25.4 mm) Optics up to 0.38" (9.5 mm) Thick

- Two #8 (M4) Counterbores for Post Mounting

The K5X1 5-Axis Kinematic Optic Mount has an optic cell that can be adjusted along 5 axes (pitch, yaw, and XYZ), with a locking screw on each axis for stability. The translating cell has SM1 (1.035"-40) internal threading for attaching Ø1" mounted optics. The cell can also be used to mount Ø1" unmounted optics up to 0.38" (9.5 mm) thick using the included SM1RR Retaining Ring, which can be tightened using the SPW602 or SPW606 Spanner Wrench (sold separately). The mount features engraved vertical and horizontal tick marks to use as an alignment aid for the mounting cell. For post mounting the K5X1 kinematic mount in a right- or left-handed configuration, two orthogonal #8 (M4) counterbores are provided.

A 5/64" hex key or ball driver (not included) can be used to adjust the five axes of the kinematic mount. Three 1/4"-80 adjuster screws with removable knobs for pitch, yaw, and z-axis adjustment can be locked with a 5/64" hex key. The X and Y axes are adjusted with two 3/16"-100 adjuster screws and can be locked with the included 0.035" hex key. If higher adjustment resolution or control is desired for the K5X1 mount, the three 1/4"-80 adjusters can be switched with DAS110 or DM22 Differential Adjusters.

For more information on our 5-axis kinematic mounts, including a Ø1/2" and Ø2" version, see our full web presentation.

- Z-axis translation is accomplished by turning all three tip/tilt adjusters equally in the same direction.

- Pitch, Yaw, and XYZ Adjustment:

- Kinematic Pitch/Yawa: ±3°, 6.2 mrad/rev

- X and Y Translation: ±0.04" (±1.0 mm), 254 µm/rev

- Z Translationb: ±0.12" (±3.0 mm), 318 µm/rev

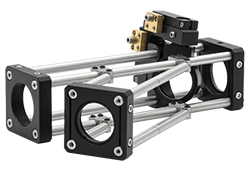

- Compatible with Our 30 mm Cage System

- SM1-Threaded Bore for Ø1" (25.4 mm) Optics up to 0.38" (9.5 mm) Thick

- Two 8-32 (M4 x 0.7) Mounting Holes for Post Mounting

The KC5X1(/M) 5-Axis Cage-Compatible Kinematic Optic Mount has an optic cell that can be adjusted along 5 axes (pitch, yaw, and XYZ). The optic cell has an internally SM1-threaded mounting hole that accepts Ø1" optics up to 0.38" (9.5 mm) thick; the optic can be secured using the included SM1RR retaining ring, which can be tightened using an SPW602, SPW606, or SPW801 Spanner Wrench. Thicker optics can be accommodated by housing the optic in one of our SM1 Series Lens Tubes and then threading the lens tube into the front plate of the mount, as shown in Figure G6.1. The front plate also features engraved vertical and horizontal lines to use as an alignment aid for the optic cell.

Click to Enlarge Figure G6.2 Adjusting the KC5X1 Mount in a Cage System Using a 564HK Hex Key

Angular and z-axis adjustment are controlled by three 1/4"-80 screws, which can be locked using F25SC1 locking collars (sold separately). X and Y axis adjustment is controlled by two 3/16"-100 screws, which can be locked using F19SC1 locking collars (sold separately). All five adjuster screws can be actuated with a 5/64" (2 mm) hex key or ball driver (not included). Additionally, the three screws for angular and z-axis adjustment have knobs, located between the front and back plates of the mount, that can be turned manually or with a 5/64" (2 mm) hex key inserted into one of 6 holes on the edge of each knob, as shown in Figure G6.2.

Two orthogonal 8-32 (M4 x 0.7) mounting holes allow the mount to be post mounted in a right- or left-handed orientation. The mount also has four clearance holes to accommodate Ø6 mm ER cage rods for compatibility with our 30 mm cage systems. Once the desired position in the cage system is achieved, 5/64" (2 mm) hex locking setscrews on the rear plate can be used to secure the rods in place.

We also offer post-mountable 5-axis kinematic mounts for other optic sizes, as well as 6-axis kinematic mounts mounts that provide pitch, yaw, XYZ, and rotational adjustment.

a. X/Y travel range of the KC5X1(/M) mount will start to diminish for pitch/yaw adjustments above ±1° due to interference with cage system rods.

b. Z-axis translation is accomplished by turning all three angular adjusters equally in the same direction.

Video 280A K6XS 6-Axis Kinematic Mount Usage

- Six Adjustment Axes with Locks

- Kinematic Pitch/Yaw: ±4° at 5 mrad/rev

- X and Y Translation: ±2 mm at 254 µm/rev

- Z Translationa: ±0.13" (±3.2 mm) at 318 µm/rev

- Continuous 360° Roll Control with 1° Graduations

- Independent X, Y, and Roll Adjustment

- SM1-Threaded Bore for Ø1" (25 mm) Optics up to 0.55" (14 mm) Thick

- Six #8 (M4) Counterbores for Post Mounting

The K6XS 6-Axis Kinematic Optic Mount is designed as a general-purpose, high-precision positioner. The optic cell can be translated along 6 axes, and each axis has a locking screw for stability. The translating cell has SM1 (1.035"-40) threading for attaching Ø1" lens tubes or mounting Ø1" (25 mm) optics up to 0.55" (14 mm) thick using the included SM1RR Retaining Ring, which can be tightened using an SPW602 or SPW606 Spanner Wrench (sold separately). The rotating dial has tapped 4-40 holes for attaching the K6A1 (sold separately below).

In testing, the K6XS was shown to drift less than 15 µrad in 48 hours at typical environmental conditions, with a 2 °C temperature fluctuation. The X and Y axes cause less than ±10 µm of crosstalk when translated over their full range. If higher adjustment resolution is desired for pitch, yaw, or z-translation, the three 1/4"-80 adjusters can be replaced with DAS110 Differential Adjusters.

For more information on our 6-axis kinematic mounts, including versions for Ø1/2" and Ø2" optics, see our full web presentation.

Click to Enlarge

Click to EnlargeFigure 337A A KCB1 and high power beamsplitter cube with a beam path enclosed by an aluminum lens tube cover and two C128CC clamps.

- Eight 4-40 Tapped Holes to Mate with 30 mm Cage Systems

- Mounts Ø1" (25.4 mm) Optics at a 45° Angle to the Optical Axis

- Provides ±4º Kinematic Tip and Tilt Adjustment

- Compatible with SM1-Threaded (1.035"-40) Lens Tubes

- Post Mountable:

The KCB1(/M) cube provides kinematic tip and tilt of an optic held in a mounting plate whose mean horizontal position is at a 45° angle. Entrance and exit ports are equipped with an SM1-threaded (1.035"-40) bore. The KCB1(/M) has eight 4-40 tapped holes center-to-center spaced to mate with our 30 mm cage system standard. ERSCB ER Rod Adapters are necessary to effectively connect, adjust, and lock two of these right-angle cage mounts together within the cage system. The kinematic tip and tilt adjustment plate on these cubes is actuated with 100 TPI (Threads per Inch) adjustment screws that allow for smooth, high-resolution movement of 0.01" (0.254 mm) per rotation. Two of these adjusters include removable knobs, while the third must be tuned with a 5/64" (2 mm) hex key or balldriver.

A nylon-tipped setscrew is used to secure Ø1" (25.4 mm) optics using a 5/64" (2 mm) hex key or balldriver via the mounts' rear-loading, double-bored hole. The rear loading design does not limit the maximum thickness of the mounted optic and the mounted optic remains accessible even after the mount is fitted with cage rods or lens tubes. The minimum thickness for optics that can be secured by these mounts is 0.12" (3 mm), and optics thinner than 0.12" (3 mm) will need to be combined with an optic spacer.

Click to Enlarge Figure 488A KCB1C Mount with Smooth Bores (Right) Directly Attached to a KCB1 Mount with Tapped Holes (Left)

- Eight 0.25" (6.35 mm) Deep Smooth Bore Holes to Mate with 30 mm Cage Systems

- Mounts Ø1" (25.4 mm) Optics at a 45° Angle to the Optical Axis

- Provides ±4º Kinematic Tip and Tilt Adjustment

- Compatible with SM1-Threaded (1.035"-40) Lens Tubes

- Post Mountable:

The KCB1C(/M) cube provides kinematic tip and tilt of an optic held in a mounting plate whose mean horizontal position is at a 45° angle. Entrance and exit ports are equipped with an SM1-threaded (1.035"-40) bore and four 0.25" (6.35 mm) deep smooth bore holes center-to-center spaced to mate with our 30 mm cage system standard. The cage rods are secured by eight setscrews using a 5/64" (2 mm) hex key or balldriver. This design allows multiple 30 mm cage components to be directly interfaced without the need for ERSCB ER Rod Adapters. The kinematic tip and tilt adjustment plate on these cubes is actuated with removable 100 TPI (Threads per Inch) adjustment screws that allow for smooth, high-resolution movement of 0.01" (0.254 mm) per rotation. Two of these adjusters include removable knobs, while the third must be tuned with a 5/64" (2 mm) hex key or balldriver.

A nylon-tipped setscrew is used to secure Ø1" (25.4 mm) optics using a 5/64" (2 mm) hex key or balldriver via the mounts' rear-loading, double-bored hole. This hole features a clearance cut that provides a maximum clear aperture for any transmitted light and allows easy access to mounted optics. The rear loading design does not limit the thickness of the mounted optic and the mounted optic remains accessible even after the mount is fitted with cage rods or lens tubes. The minimum thickness for optics that can be secured by these mounts is 0.12" (3 mm), and optics thinner than 0.12" (3 mm) will need to be combined with an optic spacer.

- Mounts 1" (25.4 mm) Elliptical Optics at a 45° Angle to the Optical Axis

- Eight 4-40 Tapped Holes for ER Cage Rods

- Provides ±4° Kinematic Pitch and Yaw Adjustment

- Z-Axis Translation Using All Three Adjusters: ±0.12" (±3.0 mm)

- 30 mm Cage System and SM1 (1.035"-40) Compatible

- Post Mountable:

The KCB1E(/M) right-angle mount provides pitch and yaw adjustment for a 1" (25.4 mm) elliptical optic held in a mounting plate whose nominal horizontal position is at a 45° angle. The ports are equipped with SM1-threaded (1.035"-40) bores and four 4-40 tapped holes center-to-center spaced to mate with our 30 mm Cage System standard. The kinematic pitch and yaw adjustment plate is actuated with 100 TPI (Threads per Inch) adjustment screws that provide angular resolution of 7.6 mrad/rev. Two of these adjusters include removable knobs, while the third must be tuned with a 5/64" (2 mm) hex key or balldriver. While the optic face is nominally centered within the mount, the third adjuster can be used for fine tuning the position along the optical axis.

A nylon-tipped adjustment screw and a nylon-coated spring clip are used to secure 1" (25.4 mm) elliptical optics using a 0.05" (1.3 mm) hex key or balldriver via the mount's rear-loading, double-bored hole. The rear loading design ensures that the optic remains accessible even after the mount is fitted with cage rods or lens tubes. These mounts were designed for a 6 mm thick optic. We offer dielectric and metallic elliptical mirrors, which are compatible with these mounts.

Click to Enlarge

Figure 586A KCB1EC(/M) Mounts have Smooth Bores for Cage Rods

- Mounts 1" (25.4 mm) Elliptical Optics at a 45° Angle to the Optical Axis

- Eight 0.25" (6.35 mm) Deep Smooth Bore Holes for ER Cage Rods

- Provides ±4° Kinematic Pitch and Yaw Adjustment

- Z-Axis Translation Using All Three Adjusters: ±0.12" (±3.0 mm)

- 30 mm Cage System and SM1 (1.035"-40) Compatible

- Post Mountable:

The KCB1EC(/M) right-angle mount provides pitch and yaw adjustment for a 1" (25.4 mm) elliptical optic held in a mounting plate whose nominal horizontal position is at a 45° angle. The ports are equipped with SM1-threaded (1.035"-40) bores and four 0.25" (6.35 mm) deep smooth bore holes spaced to mate with our 30 mm cage system standard. The cage rods are secured by eight setscrews using a 5/64" (2 mm) hex key or balldriver. This design allows multiple 30 mm cage components to be directly interfaced without the need for ERSCB ER Rod Adapters. The kinematic pitch and yaw adjustment plate is actuated with 100 TPI (Threads Per Inch) adjustment screws that provide angular resolution of 7.6 mrad/rev. Two of these adjusters include removable knobs, while the third must be tuned with a 5/64" (2 mm) hex key or balldriver. While the optic face is nominally centered within the mount, the third adjuster can be used for fine tuning the position along the optical axis.

A nylon-coated spring clip is used to secure 1" (25.4 mm) elliptical optics using a 0.05" (1.3 mm) hex key or balldriver via the mount's rear-loading, double-bored hole. The rear loading design ensures that the optic remains accessible even after the mount is fitted with cage rods or lens tubes. These mounts were designed to hold a 6 mm thick elliptical optic. We offer dielectric and metallic elliptical mirrors, which are compatible with these mounts.

Click to Enlarge

Figure 639B Beam Path Inside Right-Angle Kinematic OAP Mirror Mounts

(OAP Mirror Sold Separately)

Click to Enlarge

Figure 639A KCB1P Mounting Plate and Housing Body Shown with Off-Axis Parabolic Mirror (Sold Separately)

- Mount Ø1/2" (Ø12.7 mm) or Ø1" (Ø25.4 mm) Off-Axis Parabolic Mirrors at a Right Angle

- Eight 0.25" (6.35 mm) Deep Smooth Bore Holes for Ø6 mm ER Cage Rods

- Provides ±4° Kinematic Pitch and Yaw Adjustment

- Z-Axis Translation Using All Three Adjusters: ±0.12" (±3.0 mm)

- 30 mm Cage System and SM1 Lens Tube Compatible

- Two 1/4"-20 (M6 x 1.0) Taps for Mounting on Ø1/2" or Ø1" Posts

The KCB1P5(/M) and KCB1P(/M) right-angle mounts provide pitch and yaw adjustment for a Ø1/2" (Ø12.7 mm) (Item # KCB1P5(/M)) or a Ø1" (Ø25.4 mm) (Item # KCB1P(/M)) off-axis parabolic (OAP) mirror mounted on a plate that positions the surface of the mirror at a 45° angle. The ports are equipped with SM1-threaded (1.035"-40) bores and four 0.25" (6.4 mm) deep smooth bore holes spaced to mate with our 30 mm cage system. The cage rods are secured by eight setscrews using a 5/64" (2.0 mm) hex key or balldriver. This design allows multiple 30 mm cage components to be directly interfaced without the need for ERSCB ER Rod Adapters. The kinematic pitch and yaw adjustment plate is actuated with 100 TPI (Threads Per Inch) adjustment screws that provide an angular resolution of 7.6 mrad/rev. The knob on each adjuster is removable. While the optic face is nominally centered within the mount, the third adjuster can be used for fine tuning the position along the optical axis.

Three captive 4-40 cap screws in the optic mounting plate are used to secure the Ø1/2" (Ø12.7 mm) or Ø1" (Ø25.4 mm) off-axis parabolic mirror using a 5/64" (2.0 mm) hex key or balldriver. The rear-loading, removable mounting plate features our ball and V-groove design that allows it to be precisely kinematically positioned on the body of the mount. The plate and mount are held together using pairs of rare-earth magnets. Once mounted, the plate can be firmly secured in place using the captive locking screw with 5/64" (2.0 mm) hex on the back. The rear-loading design ensures that the optic remains accessible even after the mount is fitted with cage rods or lens tubes. The back of the mounting plate offers an engraved label for marking details about the installed mirror such as the focal length or part number. The mounting plate also features through bores for OAP mirrors with holes for the focused or collimated beams, though we do not currently stock these mirrors in a Ø1/2" or a Ø1" form factor. To request a quote for custom Ø1/2" or Ø1" OAP mirrors with holes, please contact Tech Support.

Click to Enlarge

Figure 266B Gimbal mounts in combination with our swivel couplers are ideal for creating non-45° incident angles within a cage system.

Click to Enlarge

Figure 266A The KC45D1 Gimbal Mount in a 30 mm Cage System

- True Gimbal Design

- Maximum Optic Thickness: 0.24" (6 mm)

- Mounts Ø1" Optics

- Compatible with Thorlabs' 30 mm Cage System

- Full 360° Rotation of Optic Holder

- ±30° Rotation on the Optic Holder Saddle

The KC45D1 Gimbal Mirror Mount is designed to allow a Ø1" optic to be rotated about a point in the center of a 30 mm cage assembly with true gimbal motion. The optic holder is free to rotate through 360°. Once its coarse angular orientation is set, the fine adjustment mechanism (i.e., two 100 TPI adjusters offering an adjustment per revolution of 13 mrad/rev) can be used for precise alignment, using the HKTS-5/64 hex key thumbscrew or any other 5/64" hex key or balldriver. The second angular degree of freedom is achieved by rotation of an intermediate saddle. This saddle connects the optic holder to the cage assembly and is free to rotate ±30°. The optic is secured against the back lip of the SM1 (1.035"-40) center tapped region using the included SM1RR Retaining Ring.

- Designed for Intra-Cavity Use

- Maximum Optic Thickness: 0.63" (16 mm)

- Angular Range: ±2.5°

- Angular Displacement per Revolution: 0.35°

- Post Mountable with Three 8-32 (M4) Tapped Holes

The GM100 gimbal mount for Ø1" optics is designed for intra-cavity use. 50 divisions per revolution graduated adjustment knobs are located on the top surface of the mount, making them easily accessible even if the mount is integrated into an optical cavity. This design provides pure rotational motion without angular or positional crosstalk.

- True Gimbal Design

- Maximum Optic Thickness: 0.25" (6.4 mm)

- Mounts Ø1" (25.4 mm) Optics

- Fine Adjustment Provides ±15° at 1°/rev

- Fully Lockable Design

- Superior Kinematic Performance Without Crosstalk

The GMB1 Gimbal Mirror Mount, which is designed to hold Ø1" (Ø25.4 mm) optics up to 0.25" (6.4 mm) thick, features true gimbal motion in order to eliminate crosstalk when steering a beam of light. The point of rotation for both axes is located at the center of the mounted optic’s surface. Utilizing locking thumbscrews and fine pitch adjusters, the GMB1 offers both coarse adjustment and fine tuning. The coarse adjustment allows 360° of manual positioning for both angular degrees of freedom. The fine adjustment allows for ±15° of control, with rotation of the control knob yielding 1° of angular displacement per revolution. The yaw can be adjusted in a similar fashion using the thumbscrew and setscrew closest to the post. After the desired pitch and yaw position is established, the entire mount can be easily locked into place by tightening both thumbscrews and both setscrews. The minimal profile of this mount is ideal for tight beam paths.

Products Home

Products Home

Zoom

Zoom

SM1-Compatible Kinematic Mounts

SM1-Compatible Kinematic Mounts