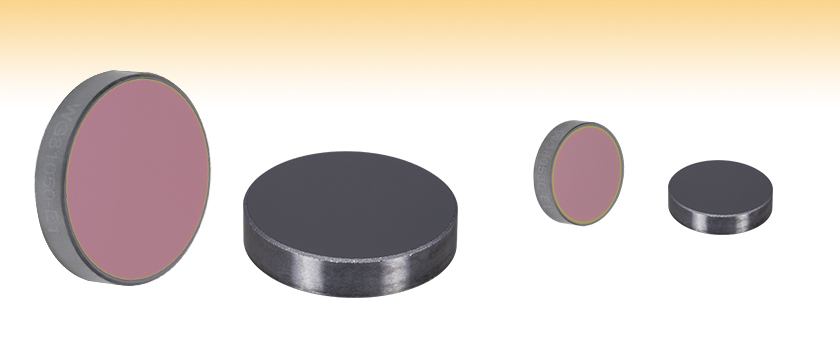

Silicon Windows

- Offered Uncoated or with AR Coating for 2 - 5 µm

- Ø1/2" and Ø1" Sizes Available

WG81050-E1

(Ø1")

WG81050

(Ø1")

WG80530-E1

(Ø1/2")

WG80530

(Ø1/2")

Please Wait

| Flat Window Selection Guide | |

|---|---|

| Wavelength Range | Substrate Material |

| 180 nm - 8.0 μm | Calcium Fluoride (CaF2) |

| 185 nm - 2.1 μm | UV Fused Silica |

| 200 nm - 5.0 μm | Sapphire |

| 200 nm - 6.0 μm | Magnesium Fluoride (MgF2) |

| 220 nm to >50 µm | CVD Diamond Windows |

| 230 nm - 1.1 µm | UV Fused Silica, Textured Antireflective Surface |

| 250 nm - 1.6 µm | UV Fused Silica, for 45° AOI |

| 250 nm - 26 µm | Potassium Bromide (KBr) |

| 300 nm - 3 µm | Infrasil® |

| 350 nm - 2.0 μm | N-BK7 |

| 600 nm - 16 µm | Zinc Selenide (ZnSe) |

| 1 - 1.7 µm | Infrasil®, Textured Antireflective Surface |

| 1.2 - 8.0 μm | Silicon (Si) |

| 1.9 - 16 μm | Germanium (Ge) |

| 2 - 5 μm | Barium Fluoride (BaF2) |

| V-Coated Laser Windows | |

Features

- 1/2" and 1" Diameters Available

- Ideal for IR Applications in the 1.2 - 8.0 µm Spectral Range

- Available Uncoated or AR Coated for <1.25% Average Reflectance from 2 - 5 µm

Thorlabs' Precision Monocrystalline Silicon (Si) Windows are offered in Ø1/2" and Ø1" sizes. They are available uncoated or with an AR coating on both sides that provides <1.25% average reflectance from 2 - 5 µm (see the Graphs tab for more details). Silicon offers high thermal conductivity and low density, making it suitable for laser windows. However, since silicon has a strong absorption band at 9 µm, it is not suitable for use with CO2 laser transmission applications.

Thorlabs also offers precision windows fabricated from several other substrates for use in a large variety of laser and industrial applications. For our complete selection, see the Flat Window Selection Guide table to the right. We also offer wedged silicon windows, laser windows with AR coatings centered around commonly used laser wavelengths, and Brewster windows designed to eliminate P-polarized reflected light.

Click to Enlarge

Click for Raw Data

This graph shows the measured transmission of an uncoated silicon window at normal incidence.

Click to Enlarge

Click for Raw Data

This plot gives the measured total transmission of a 5 mm thick, AR-coated silicon window at normal incidence. The blue shaded region denotes the AR coating range, over which Tavg > 94%. Performance outside the specified range is not guaranteed and varies from lot to lot.

Click to Enlarge

Click for Raw Data

This plot gives the measured reflectance (per surface) at normal incidence of our 5 mm thick, AR-coated silicon window. The average reflectance is <1.25% per surface within the shaded wavelength range of 2 µm - 5 µm.

| Posted Comments: | |

user

(posted 2024-11-01 02:47:23.037) The 'E coated' silicon windows (WG81050-E) come with a hazardous materials warning on the box (uncoated Silicon windows have no warning on the box). Are you able to say what the hazardous aspect of the E coating is? blarowe

(posted 2024-11-07 09:35:04.0) Thank you for contacting Thorlabs. I'm very sorry for the confusion here. It will actually be the silicon itself leading to that warning, and the uncoated windows should have similar warnings. blarowe

(posted 2024-11-07 09:35:04.0) Thank you for contacting Thorlabs. I'm very sorry for the confusion here. It will actually be the silicon itself leading to that warning, and the uncoated windows should have similar warnings. Iga Kamińska

(posted 2023-11-10 11:08:47.737) Could you please, send me information about the microroughness value?

Is the Si window poished both sides? jpolaris

(posted 2023-11-21 03:54:22.0) Thank you for contacting Thorlabs. Yes, these Silicon windows are polished on both sides. Unfortunately, we have not characterized the microroughness of these Silicon windows at this time. Felix

(posted 2023-10-16 11:01:03.933) Hello,

is the Silicon-Window a single-crystal?

Whats the orientation and do you have precise measurements of the mechanical properties (elastic modulus, poisson ratio, density). jdelia

(posted 2023-10-19 01:33:14.0) Thank you for contacting Thorlabs. These Silicon Windows are high-resistance, Optical Grade, Czochralski Monocrystals. The OEM for this material uses both 111 and 100 orientations for the windows, however there is no flat side to mark the lattice orientation of the windows. You can find the mechanical properties of Silicon in our optical substrates tutorial here: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=6973&tabname=silicon. Morken Michael

(posted 2022-09-13 09:52:38.957) Is there a reflection spectrum available for the uncoated Silicon? cdolbashian

(posted 2022-09-26 04:43:24.0) Thank you for reaching out to us Morken. While we do not have experimental data for the cumulative reflections for the uncoated Si windows, I think it is very feasible to use Fresnel reflection coefficient in conjunction with the Sellmeier equation in order to make a fair estimate of the reflection as a function of wavelength. I have contacted you directly with some suggestions regarding the execution of this calculation. bill sweatt

(posted 2022-02-03 15:31:58.833) What is the maximum temperature for good transmission for your silicon windows? cdolbashian

(posted 2022-02-09 05:06:49.0) Thank you for reaching out to us at Thorlabs! At room temperature we would expect ~50% transmission. Based on some findings in literature, it seems like the transmission is nominally unaffected until temperatures exceeding 300C, and even at 300C the transmission only seems to drop to about 47%. I don't think we would recommend using them in excess of 300C as a general recommendation. Benjamin Judkewitz

(posted 2019-05-07 15:52:01.43) Do these exist with AR coarting at 1700 nm? nbayconich

(posted 2019-05-13 01:00:36.0) Thank you for contacting Thorlabs. We can provide custom coating options upon request, I will reach out to you directly to discuss our custom capabilities. feng

(posted 2018-03-07 13:23:46.233) Hello, do you have a coating from 1.8 um to 3um? just like the silicon wedge provided by your company. llamb

(posted 2018-03-30 01:53:32.0) Hello, thank you for contacting Thorlabs. We do not have a standard silicon flat window with that anti-reflection coating, however we may be able to offer a custom product. If you are looking for the flat silicon window but with the 2- 5 um AR coating as on our silicon wedged windows, this particular coating run is not offered frequently so there would be a long lead time. I will reach out to you directly to discuss quoting. eugen.wiens

(posted 2015-04-27 12:42:14.043) Hello, what crystal growth process was used for this substrates, what purity does the material have, and how is the crystal oriented in respect to the window's optical axis? jlow

(posted 2015-05-13 11:25:05.0) Response from Jeremy at Thorlabs: The silicon windows we sell are only qualified by the optical properties we specified. The growth process, exact purity, and crystal orientation are not controlled explicitly. a.wienke

(posted 2014-04-29 11:23:19.87) Hi,

Do you also have any transmission data below 2.0 µm? Down to 1.9 µm would be fine for me. jlow

(posted 2014-04-29 05:08:28.0) Response from Jeremy at Thorlabs: I will send you this information directly. elharel

(posted 2014-02-11 17:32:46.72) Is this amorphous or crystalline silicon? jlow

(posted 2014-02-13 09:01:28.0) Response from Jeremy at Thorlabs: These are monocrystalline Si. tcohen

(posted 2012-05-09 16:09:00.0) Update from Tim at Thorlabs: Unfortunately, our standard –C coating is typically used with materials of much lower index and would not yield positive results on a Silicon substrate. I have contacted you to continue this discussion. tcohen

(posted 2012-05-09 14:12:00.0) Response from Tim at Thorlabs: Thank you for your feedback! We do have 1550 nm AR coated windows utilizing different substrates. For this substrate, we may be able to offer a special with our standard –C coating. I will contact you to get more information on your application and to continue this conversation. goetz

(posted 2012-05-08 11:24:40.0) This product would be useful to me if it were AR coated for 1550 nm. |

| Window Selection Guide (Table Sorted by Wavelength) | |||||

|---|---|---|---|---|---|

| Substrate and Window Type | Wavelength Range | Available AR Coatings | Reflectance over AR Coating Rangea | Transmission Data | Reflectance Data |

| Calcium Fluoride (CaF2): Flat or Wedged |

180 nm - 8.0 μm | Uncoated | - | Raw Data |

- |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| UV Fused Silica: Flat, Wedged, V-Coated Flat, or V-Coated Wedged |

185 nm - 2.1 μm | Uncoated (Flat or Wedged) |

- | Raw Data |

- |

| -UV Coating, 245 - 400 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C3 Coating, 261 - 266 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C6 Coating, 350 - 450 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -A Coating, 350 - 700 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -B Coating, 650 - 1050 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C Coating, 1050 - 1700 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| Sapphire: Flat or Wedged |

200 nm - 5.0 μm | Uncoated | - | Raw Data |

- |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0% at 0° AOI | Raw Data |

Raw Data |

||

| -E1 Coating, 2.0 - 5.0 µm | Ravg < 1.50%, Rabs < 3.0% (per Surface, 2.0 - 5.0 µm); Ravg < 1.75% (per Surface, 2.0 - 4.0 µm) at 0° AOI |

Raw Data |

Raw Data |

||

| Magnesium Fluoride (MgF2): Flat or Wedged |

200 nm - 6.0 μm | Uncoated | - | Raw Data |

- |

| Barium Fluoride (BaF2): Flat or Wedged |

200 nm - 11 µm | Uncoated (Wedged Only) |

- | Raw Data |

- |

| -E1 Coating, 2 - 5 µm | Ravg < 1.25%; Rabs < 2.5% at 0° AOI | Raw Data |

Raw Data |

||

| UV Fused Silica, for 45° AOI: Flat or Wedged |

250 nm - 1.6 µm | Coating for 250 nm - 450 nm |

Ravg < 1.0% at 45° AOI | Raw Data |

|

| Coating for 350 nm - 1100 nm |

Ravg < 2.0% at 45° AOI | Raw Data |

|||

| Coating for 400 nm - 700 nm |

Ravg < 1.0% at 45° AOI | Raw Data |

|||

| Coating for 600 nm - 1700 nm |

Ravg < 1.5% at 45° AOI | Raw Data |

|||

| Coating for 700 nm - 1100 nm |

Ravg < 1.0% at 45° AOI | Raw Data |

|||

| Coating for 1200 nm - 1600 nm |

Ravg < 1.0% at 45° AOI | Raw Data |

|||

| Potassium Bromide (KBr): Flat |

250 nm - 26 µm | Uncoated | - | - | |

| Infrasil®: Flat |

300 nm - 3 µm | Uncoated | - | Raw Data |

- |

| N-BK7: Flat, Wedged, V-Coated Flat, or V-Coated Wedged |

350 nm - 2.0 μm | Uncoated (Flat or Wedged) |

- | Raw Data |

- |

| -A Coating, 350 - 700 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C7 Coating, 400 - 700 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C10 Coating, 523 - 532 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C11 Coating, 610 - 860 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -B Coating, 650 - 1050 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C13 Coating, 700 - 1100 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| C14 Coating, 1047 - 1064 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C15 Coating, 523 - 532 nm & 1047 - 1064 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C Coating, 1050 - 1700 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| Zinc Selenide (ZnSe): Flat or Wedged |

600 nm - 16 µm | Uncoated | - | Raw Data |

- |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| -E4 Coating, 2 - 13 µm (Only Flat) |

Ravg < 3.5%; Rabs < 6% at 0° AOI | Raw Data |

Raw Data |

||

| -E2 Coating, 4.5 - 7.5 µm (Only Flat) |

Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| -E3 Coating, 7 - 12 µm (Only Wedged) |

Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| -G Coating, 7 - 12 µm (Only Flat) |

Ravg < 1% at 0° AOI | Raw Data |

Raw Data |

||

| Silicon (Si): Flat or Wedged |

1.2 - 8.0 μm | Uncoated | - | Raw Data |

- |

| -E1 Coating, 2 - 5 µm (Only Wedged) |

Ravg < 1.25%; Rabs < 2.5% at 0° AOI | Raw Data |

Raw Data |

||

| -E Coating, 3 - 5 µm (Only Flat) |

Ravg < 2% at 0° AOI | Raw Data |

Raw Data |

||

| Germanium (Ge): Flat or Wedged |

1.9 - 16 μm | Uncoated, 2.0 - 16 μm | - | Raw Data |

- |

| -C9 Coating, 1.9 - 6 µm (Only Flat) |

Ravg < 2% at 0° AOI | Raw Data |

Raw Data |

||

| -E3 Coating, 7 - 12 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| Item # | WG80530 | WG81050 |

|---|---|---|

| Diameter | 1/2" (12.7 mm) | 1" (25.4 mm) |

| Diameter Tolerance | +0.0 / -0.2 mm | |

| Thickness | 3.0 mm | 5.0 mm |

| Thickness Tolerance | ±0.1 mm | |

| Clear Aperture | >90% Diameter | |

| Parallelism | ≤2 arcmin | |

| Surface Flatnessa | λ/2 over Clear Aperture | |

| Surface Quality | 40-20 Scratch-Dig | |

| Wavelength Range | 1.2 - 8.0 μm (Uncoated) | |

| Substrate | Siliconb | |

| Transmission Data | Raw Data |

|

| Item # | WG80530-E1 | WG81050-E1 |

|---|---|---|

| Diameter | 1/2" (12.7 mm) | 1" (25.4 mm) |

| Diameter Tolerance | +0.0 / -0.2 mm | |

| Thickness | 3.0 mm | 5.0 mm |

| Thickness Tolerance | ±0.3 mm | |

| Clear Aperture | ≥90% Diameter | |

| Parallelism | <3 arcmin | |

| Surface Flatnessa | ≤λ/2 over Clear Aperture | |

| Surface Quality | 40-20 Scratch-Dig | |

| AR Coating Range | 2 - 5 µm (-E1 Coating) | |

| AR Coating Reflectanceb | Ravg < 1.25%c; Rabs < 2.5% (0° AOI) | |

| Reflectance Data | Raw Data |

|

| Substrate | Silicond | |

| Transmission Data | Raw Data |

|

Products Home

Products Home

Zoom

Zoom

Silicon Windows, 1.2 - 8.0 µm

Silicon Windows, 1.2 - 8.0 µm