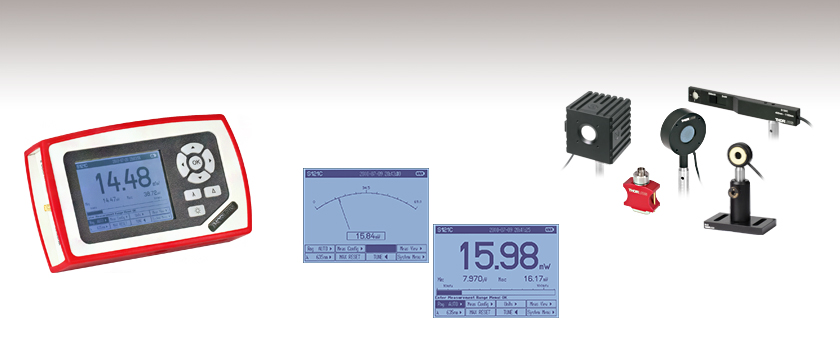

Digital Handheld Optical Power and Energy Meter Console

- Power and Energy Measurements for Free Space and Fiber Applications

- Designed for High Accuracy, Reliability, and Ease of Use

- Over 25 Compatible Sensors

PM100D

Multiple Display

Options

Photodiode, Fiber, Integrating

Sphere, Thermal, and Pyroelectric

Sensors Available

Detector Options

Please Wait

| Item # | PM100D |

|---|---|

| Compatible Sensors | Photodiode, Thermal, and Pyroelectrica |

| Optical Power Rangeb | 100 pW to 200 W |

| Optical Energy Rangeb | 10 µJ to 15 J |

| Available Sensor Wavelength Rangeb | 185 nm - 25 μm |

| Max Repetition Rateb | 3 kHz |

| Display Refresh Rate | 20 Hz |

| Bandwidtha | DC - 100 kHz |

| Photodiode Sensor Rangec | 50 nA - 5 mA |

| Thermopile Sensor Rangec | 1 mV - 1 V |

| Pyroelectric Sensor Rangec | 100 mV - 100 V |

| Power Meter Selection Guide |

|---|

| Sensors |

| Photodiode Power Sensors |

| Thermal Power Sensors |

| Thermal Position & Power Sensors |

| Pyroelectric Energy Sensors |

| Power Meter Consoles |

| Digital Handheld Console |

| Analog Handheld Console |

| Touchscreen Handheld Console |

| Dual-Channel Benchtop Console |

| Complete Power Meters |

| Power Meter Bundles |

| Wireless Power Meters with Sensors |

| Compact USB Power Meters |

| Field Power Meters for Terminated Fibers |

| USB Interfaces, External Readout |

Features

- Handheld Digital Power Meter Console

- Designed for Coherent and Incoherent Light Source Measurements

- Power and Energy Measurements for CW and Pulsed Source Detection

- Advanced Measurement Capabilities

- Large 4" LCD Display with Multiple Display Options

- Compatible with Over 25 Sensors (Shown Below)

- Pre-Installed 8 GB SD Memory Card for Storing and Transferring Data

- USB 2.0 Interface

- Long-Life Internal Li-Polymer Battery

- Sensor Upgrade and Recalibration Services Available

- Optical Power Monitor PC Software Available (See Software Tab for Details)

The PM100D is the cornerstone of Thorlabs' optical power and energy meter consoles and is the digital counterpart to the PM100A analog power meter console. The console (and sensor, sold separately) is ideal for use as a CW and pulsed source power meter, incoherent optical source power meter, general light power meter, fiber power meter, and more. The display on the PM100D features adjustable brightness settings, with the option to turn off the backlight completely while still being readable.

The PM100D is compatible with more than 25

This power and energy meter console is also available as a kit, bundled with our most popular sensors. Please visit our power meter kits page for more information. If you have any questions regarding these kits, or would like to suggest other kit options, please contact Tech Support with inquiries.

For a touchscreen version of the PM100D with more advanced spectral correction features, inputs for temperature and humidity sensors, data logging, and additional memory, we offer the PM400 capacitive touchscreen power and energy meter console. We also offer wireless, handheld, self-contained power meters, which feature an ultra-slim sensor with a built-in OLED display as well as Bluetooth® and USB features.

Console Design

The compact housing has a large, 4” backlit display with a resolution of 320 x 240 pixels and illuminated buttons, all of which make operation in dark labs easy. The LCD’s clear GUI offers easy data readouts with an intuitive navigation scheme. Interactive tooltips help to operate the device by giving the user step-by-step operating instructions, displaying the next step on the screen.

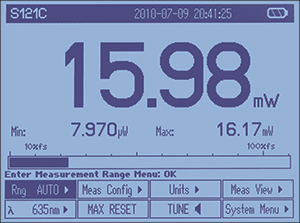

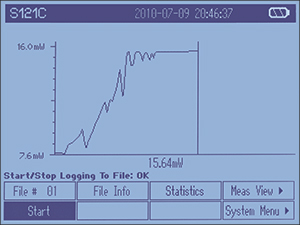

The PM100D features four standard measurement screens. The first option is a numeric readout useful for standard power and energy readings. The second option is a tuning needle typically seen on analog devices, however, optimized to run as a digital readout on the display screen. Third is a tuning graph, which is very convenient for fine tuning CW and pulsed sources.

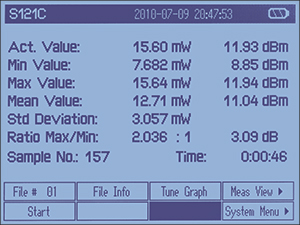

The unit can also be run in a data acquisition mode. Simply start the scan and the unit automatically starts recording data such as current power/energy, minimum, maximum, standard deviation, and other important statistics recorded over the acquisition period. The PM100D also features several user customizable displays and audio tuning for use when the detector is not within visual range. See the Display Screens tab for further information.

Click to Enlarge

Thorlabs' C-Series Power Meter Sensor Connectors Include the Sensor Calibration Data

Connectivity

The sensor connector, shown to the left, enables "hot swappable" quick sensor exchange. The sensor connectors contain all the sensor information including NIST-traceable responsivity curves, sensor types, and model number.

A slot for an SD memory card (an 8 GB SD card is pre-installed) allows data recording even in stand-alone operation, giving the user large memory storage when recording data in the field or away from a computer in the lab. Data can also be recorded via the USB PC connection and optical power monitor software. This software is capable of handling up to eight consoles simultaneously. The features of the PC control software are highlighted in the Software tab.

In addition to remote control operation and data logging/recording, the USB connection can also act as the charging system for the Li-Polymer battery. Also included is an AC battery charger which uses an intelligent charging management system to improve battery lifetime and reduce battery memory effects.

Recalibration Service

Recalibration services are available for our thermal and photodiode power sensors, pyroelectric energy sensors, and consoles. We recommend your Thorlabs sensor and console be recalibrated as a pair; however, each may be recalibrated individually. To order this service for your sensor or console, scroll to the bottom of the page and select the appropriate Item # that corresponds to your sensor or console. Recalibration of a single-channel console is included with the recalibration of a sensor at no additional cost.

Sensor Upgrade Service

Thorlabs' current line of C-Series sensors and power meter consoles are not compatible with old power meter consoles and sensor heads, respectively. We offer a sensor upgrade service if you want to use your existing sensors with a new power meter console. Note: upgraded sensors will be incompatible with old power meter consoles and new sensors converted to work with older consoles will not be compatible with the PM100D. Please contact our Tech Support team for details.

| Item # | PM100D |

|---|---|

| Display | |

| Display Type | Graphical LCD 320 x 240 pixels, LED Backlight |

| Display Screens | Numerical, Bar Graph, Line Graph, Statistics, Simulated Analog Needle |

| Viewing Area | 81.4 mm x 61.0 mm (3.20" x 2.40") |

| Refresh Rate | 20 Hz |

| Audio | 1x Speaker |

| Sensor Interface | |

| Compatible Sensors | All Photodiodes, Thermopiles, and Pyrosa See Below for Full Sensor Specs |

| Time Constant Correction | <1 s |

| AD Converter | 16 bit |

| Trigger (Pulse Measurements, Pyroelectric Sensors) | Adjustable, 0.1 - 100% |

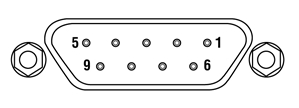

| Connector | DB9F, Left Side |

| Sensor Temperature Control | Thermistor |

| Temperature Range | -10 to 80 °C |

| Analog Outputs | |

| Signal | Amplified Input Signal (Not Corrected) |

| Voltage Range | 0 to 2 V |

| Accuracy | ±3% |

| Bandwidth | Up to 100 kHz, Dependent on Sensor and Settings |

| Connector | SMA, Left Side |

| Digital Outputs | |

| Memory | 8 GB Removable SD Card |

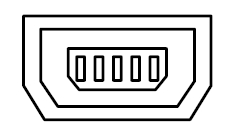

| Connector / Interface | Mini USB / USB 2.0 |

| Power | |

| Battery | Li-Polymer, 3.7 V, 1300 mAh |

| Charger / DC Input | 5 V / 1 A |

| Dimensions and Mounting | |

| Dimensions (L x W x H) | 180 mm x 105 mm x 38 mm (7.09" x 4.13" x 1.50") |

| Weight | <0.5 kg (<1.1 lb) |

| Mounting Options | Kickstand; 1/4"-20 Post Thread |

| Operating Temperature | 0 to 40 °C |

| Storage Temperature | -40 to 70 °C |

Sensor Compatibility Specs

| Item # | PM100D | ||

|---|---|---|---|

| Detector Compatibility | Photodiode Sensors: S1xxC Series Photodiodes (Max 5 mA) |

Thermal Sensors: S3xxC Series Thermopiles (Max 1 V) |

Pyroelectric Sensors: ESxxxC Series Pyros (Max 100 V)a |

| Measurement Ranges | 6 Decades; 50 nA - 5 mA Ranges Selectable in W or A, Sensor Dependent |

4 Decades; 1 mV - 1 V Ranges Selectable in W or V, Sensor Dependent |

4 Decades; 100 mV - 100 V Ranges Selectable in J or V, Sensor Dependent |

| Wavelength Ranges | 200 nm - 1800 nm (Sensor Dependent) | 190 nm - 25 μm (Sensor Dependent) | 185 nm - 25 μm (Sensor Dependent) |

| Power / Energy Ranges | 100 pW - 20 W | 100 μW - 200 W | 10 μJ - 15 J |

| Units | W, dBm, W/cm2, A | W, dBm, W/cm2, V | J, J/cm2, W, W/cm2, V |

| Accuracy | ±0.2% of Full Scale (5 µA - 5 mA) ±0.5% of Full Scale (50 - 500 nA) |

±0.5% of Full Scale (10 mV - 1 V) ±1% of Full Scale (1 mV) |

±0.5% of Full Scale (100 mV - 100 V) |

| Display Resolution | 1 pA / Responsivity Value (A/W) | 1 µV / Responsivity Value (V/W) | 100 µV / Responsivity Value (V/J) |

| Bandwidth | DC - 100 kHz, Dependent on Sensor and Settings | DC - 10 Hz, Dependent on Sensor and Settings | N/A |

| Max Repetition Rate | N/A | N/A | 3 kHz |

| Wavelength Correction | Sensor Dependent; nm (A/W) | Sensor Dependent; nm, (V/W) | Sensor Dependent; nm, (V/J) |

For a full list of the sensor head specifications please visit the Photodiode Power Sensors, Thermal Power Sensors, or Pyroelectric Energy Sensors pages. For other information, please contact Tech Support.

Features

- Header line with sensor information, date/time and battery state

- Status line with warning annunciators Bar graph and configurable left and right sub display areas to display a minimum and a maximum value or a ratio of both values (numerical screen only)

- Tool tip text above the menu

- Easily accessible menu soft buttons

| GUI Overview | ||

|

On the top bar, the sensor, date and time, and battery life indicator are shown. The main window contains one of the six standard display views described below. Here, the numerical readout is shown along with min and max values. Below the main window is a bar graph displaying relative and absolute changes in power and energy. The bottom bar on the PM100D contains the eight menus controlled by the D-pad. |

These menus at the bottom of the display access all the standard and customizable displays on the PM100D. The text display above the sub menus provides further assistance in navigating these menus. Power and energy range, wavelength, measurement configuration, units, audio tuning, measurement views, and the system menu are all accessible from this bottom menu. The bottom menu also allows customization of the display screen to include frequency, power density, and min and max values. |

|

| Numeric Screen (Power Mode) | Statistics Screen (Power Mode) | ||

| This display combines a clear numerical 4-digit read out of the optical power, a bar-graph function with zooming capabilities, and configurable sub displays. | The statistics display shows the actual, minimum, maximum and mean power values in linear and logarithmic representation; further the standard deviation, the max/min ratio, the number of samples and the elapsed time. | ||

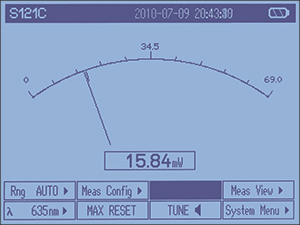

| Trend Graph (Power Mode) | Needle Tuning (Power Mode) | ||

| For laser tuning and beam alignment to visualize changes and trends together with an additional 4-digit numerical value of the absolute power. | A display imitating an analog needle together with an additional 4-digit numerical value for laser tuning tasks. A special feature is a resettable max hold indicator and a shiftable tuning sound. | ||

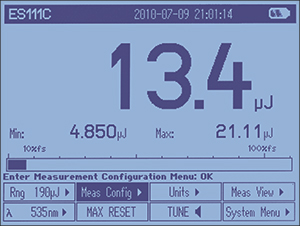

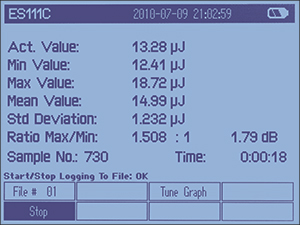

| Pulsed Numeric Screen (Energy Mode) | Pulsed Statistics Screen (Energy Mode) | ||

| This display combines a clear numerical 4-digit read out of the optical energy, a bar-graph function with zooming capabilities, and configurable sub displays. | The statistics display shows the actual, minimum, maximum and mean energy values in linear and logarithmic representation; further the standard deviation, the max/min ratio, the number of samples and the elapsed time. | ||

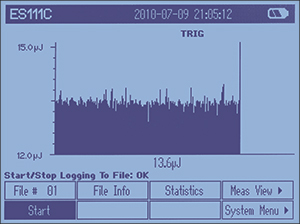

| Pulse Bar Graph (Energy Mode) | |||

| Like the Trend Graph (Power Mode) this easily shows changes and trends together with an additional 4-digit numerical value of the absolute energy of incident beam pulses. | |||

The user can customize the display screen by selecting various measurement tasks to be shown on the screen. Some screens are partly configurable by the user, for example, the user can display the min and max values within a certain time period or enable visual and audible peak indicator as a tuning aid. The display on the PM100D features adjustable brightness settings, with the option to turn off the backlight completely while still being readable.

PM100D Sensor ConnectorsD-type Female

|

Analog OutputSMA Female

0 ... 2 V | Computer ConnectionUSB Type Mini-B

USB Type Mini-B to Type A Cable Included |

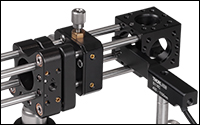

Standard Photodiode Sensor Mounting Options

The compact design of Thorlabs' Standard Photodiode Sensors allows easy integration into existing setups. Typical mounting configurations including post, cage, and lens tube options are available. Shown on this page are several different choices for mounting these sensors.

The Standard Photodiode Sensors are compatible with all S120-xx series fiber adapters. FC/PC and SMA adapters are shown on the right. Adapters for FC/APC, SC, LC, and ST connections are also available.

Flip mounts are convenient for quick power measurements from a static location. The sensor can be placed in the path of the laser beam for the power measurement and flipped down during normal operation of the system.

FM90(/M) Right-Angle Flip Mounts are shown to the right. Thorlabs also offers the TRB1(/M) Articulating Post Mount. The lockable articulating mount offers almost unlimited positioning of the sensor head.

The Standard Photodiode Sensors also feature externally SM1-threaded connections on the front face. The SM1 threading provides easy mounting to 1" lens tube systems and quick-release mounts.

Shown to the right are the KB1P(/M) Quick-Release Post Mount and QRC1A Quick-Release 30 mm Cage Mount. Both mounts feature SM1-threaded connections to the sensor heads.

Note: Due to the thickness of the S12xC sensor, the QRC1A and CP44F (shown below) quick-release mounts can only be fully removed from the cage system by backing them off an open end. The two mounts are easily removed from the cage system if only three cage rods are used. See the picture on the right.

Thorlabs also offers the CP44F 30 mm Cage Plates with Quick-Release Mounts. These mounts feature magnetically coupled front and back plates for easy and repeatable mounting.

Note: Like the QRC1A, the CP44F cannot be removed from a closed cage system.

Slim Photodiode Sensor Mounting Options

Thorlabs' Slim Photodiode Sensors are designed to fit into space-restricted environments such as 30 mm cage systems and optic-dense free-space arrangements.

Shown to the right is a S130C Sensor inserted into a 30 mm cage system. The application shown highlights the ease with which the sensor can be inserted into the cage, and the minimal space needed to take a power measurement.

The Slim Photodiode Sensors may also be mounted on a TRB1(/M) Articulating Mount. This mount allows repeatable insertion of the sensor into tight optic arrangements. After the measurement is made, the sensor may be rotated out of the beam path for normal operation.

Compact Slim Photodiode Sensor Mounting Options

Thorlabs' Compact Slim Photodiode Sensors are designed to fit into even tighter spaces such as 16 mm cage systems, our slotted Ø1/2" lens tubes, and other optic-dense free-space arrangements.

Shown to the right is an S116C Sensor inserted into a 16 mm cage system. The application shown highlights the ease with which the sensor can be inserted into the cage, and the minimal space needed to take a power measurement.

The compact slim photodiode sensor has two 8-32 (M4) taps for post mounting. One tap mounts the sensor horizontally, as seen to the right, and one allows it to be mounted vertically. The sensor may also be mounted on a TRB1(/M) Articulating Mount. This mount allows repeatable insertion of the sensor into tight optic arrangements. After the measurement is made, the sensor may be rotated out of the beam path for normal operation.

Microscope Slide Photodiode Sensor Mounting Options

S170C Mounted on a Post

The S170C may be post mounted via the 8-32 (M4 x 0.7) tap in the side of the housing.

Thorlabs' Microscope Slide Power Sensors are designed so they can be mounted directly in a microscope slide holder. The 76.0 mm x 25.2 mm x 5.0 mm sensor head has the same footprint as a standard microscope slide and is compatible with most standard upright and inverted microscopes. The photo to the right shows the S170C power sensor flipped over so that the engraved back of the housing can be used for alignment.

The S170C, S171C, and NS170C power sensors also have an 8-32 (M4 x 0.7) tap for post mounting. In the photo to the far right, an RA90(/M) is used with two Ø1/2" posts to mount the S170C sensor head in a horizontal orientation.

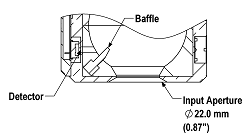

Integrating Sphere Photodiode Sensor Mounting Options

Thorlabs' Integrating Sphere Photodiode Sensor provides a low-loss cavity for diverging, non-uniform, or off-axis beam measurements. These integrating spheres are ideal for all fiber-based applications due to the beam divergence at the end of the fiber.

Shown to the right is an S140C Integrating Sphere with S120-FC Fiber Adapter. Also shown is an S140C with an S140-BFA Bare Fiber Adapter. The Bare Fiber Adapter features a mounting clamp and light shield to decrease interference from ambient light.

Compact Fiber Photodiode Sensor Mounting Options

Thorlabs' Compact Fiber Photodiodes are the ideal choice for a portable, fiber-coupled power meter. The S15xC sensors are compatible with a wide variety of fiber connections. PM20-xx adapters are available to couple FC, APC, SMA, ST, SC, and LC connectors with the sensors. Shown to the right is an S150C Sensor with FC and SMA connector adapters.

Shown to the far right is a PM100D console with S150C sensor connected to a FC connectorized optical fiber. This setup is ideal for portable use in the lab or in the field.

Pyroelectric Energy Sensor Mounting Options

Thorlabs' Pyroelectric Energy Sensors are ideal for measuring pulsed sources. These pyroelectric sensors provide direct energy readings for those sources. The sensors are designed to handle medium- to high-energy pulses from excimer, YAG, and other high-power lasers.

Each sensor ships with an insulating adapter for Ø1/2" post mounting, and they are also compatible with our 30 mm cage system, as shown to the right.

Compatible Power Meters

- Consoles:

- PM100A Analog Power and Energy Meter Console

- PM100D Digital Power and Energy Meter Console

- PM400 Capacitive Touchscreen Power and Energy Meter Console

- PM5020 Dual-Channel Benchtop Optical Power and Energy Meter Console (Version 4.0 or Later)

- Complete Power Meters:

- PM160, PM160T, and PM160T-HP Wireless Handheld Power Meters with Bluetooth® Technology

- PM16 Series Compact USB Power Meters

- PM60 and PM61 Fiber Optic Power Meter Series (Version 6.0 or Later)

- Interfaces:

- PM101 Series Power Meter Interfaces with External Readout (Version 2.0 or Later)

- PM102 Series Power Meter Interfaces with External Readout (Version 2.1 or Later)

- PM103 Series Power Meter Interfaces with External Readout (Version 3.0 or Later)

- PM100USB USB Interface Digital Power and Energy Meter

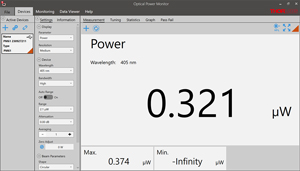

Optical Power Monitor

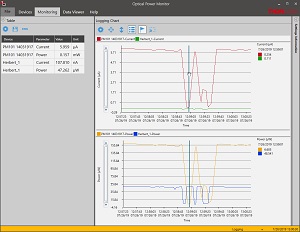

The Optical Power Monitor GUI software features power measurement, readout from up to eight power meters, and remote wireless operation.

For details on specific software features, please see the user manual.

Users interested in the legacy Power Meter Software can find it by visiting the software page.

The PM101 Series Power Meters are only compatible with version 2.0 or later. The PM102 Series Power Meters are only compatible with version 2.1 or later. The PM103 Series Power and Energy Meters are only compatible with version 3.0 or later. The PM5020 Console is only compatible with version 4.0 or later. The PM60 and PM61 Power Meter Series are only compatible with version 6.0 or later.

Optical Power Monitor GUI Software for Touchscreen, Handheld, and USB-Interface Power Meters

Features

- Operate up to Eight Power Meters Simultaneously

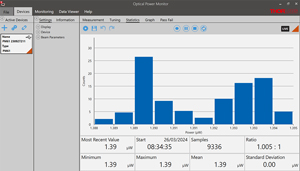

- Record and Analyze Measurements in Real Time

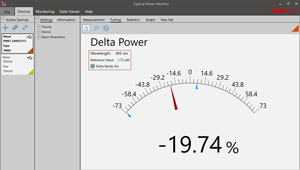

- Intuitive Analog Display and Graphing Modes

- Configurable Long-Term Data Logging

- Also Supports Position Measurements with Thermal Position & Power Sensors

- Compatible with USB and Bluetooth® Connections

The Optical Power Monitor software GUI enables seamless control of up to eight power meters that are connected via USB, RS232, or Bluetooth® wireless technologya. The latest software, firmware, drivers, and utilities for these power meters can be downloaded here.

Multiple data measurement and analysis functions are integrated into the GUI package. The interface offers a user-friendly design with minimal use of color and low brightness that is ideal use in dark lab environments while wearing laser safety glasses. Measured data can be displayed in real time as a simulated analog needle, digital values, line graph, or bar graph. Continuously logged and short-term measurements can be recorded for data viewing and analysis at a later point. A built-in statistics mode analyzes measured data and continuously updates to reflect new measurements within the pre-determined measurement period. Beam position measurements are also supported when used with our thermal position & power sensors.

The Optical Power Monitor software package installs the GUI, which then can be used to control the touchscreen, handheld, or USB-interface power meters. Firmware updates for supported power meters are also available. Programming examples and drivers for interfacing with our power and energy meter consoles using LabVIEW, C/C++, Visual C#, and Python are installed with the software; refer to the manual for details.

Please note that the Optical Power Monitor Software uses different drivers than the Power Meter Utilities Software and Thorlabs recommends using the new driver TLPM.dll. For users who wish to use the legacy Power Meter Software or use custom software designed using the older PM100D.dll driver, a Power Meter Driver Switcher program is included for easy swapping of the installed driver between the two versions.

a. The PM61 Series, PM160, PM160T, and PM160T-HP power meters are equipped with Bluetooth® connections.

Click to Enlarge

Power Measurement Mode: Set up and configure up to eight power meters.

Click to Enlarge

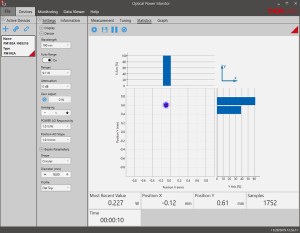

Power Tuning Mode: Simulated analog needle and digital measurement value provided. Delta Mode, enabled above, shows the fluctuation range during the measurement period.

Click to Enlarge

Power Statistics Mode: Calculate numerical statistics for a pre-determined measurement period. The panel displays the analyzed values in a bar graph and the results as numerical values.

Click to Enlarge

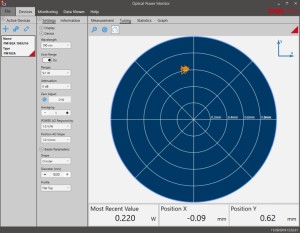

Position Tuning Mode: Tuning mode can be used with a thermal position & power sensor to aid in beam alignment.

Click to Enlarge

Position Statistics Mode: Statistics mode also provides aggregate information for thermal position & power sensors.

Click to Enlarge

Data Logging: Enable long-term measurement and simultaneous recording from up to eight power meters. Save data as .csv files for later processing while measurement results are displayed in a graph in real time.

Click to Enlarge

The PM160 wireless power meter, shown here with an iPad mini (not included), can be remotely operated using Apple mobile devices.

This tab outlines the full selection of Thorlabs' power and energy sensors. Refer to the lower right table for power meter console and interface compatibility information.

In addition to the power and energy sensors listed below, Thorlabs also offers all-in-one, wireless, handheld power meters and compact USB power meter interfaces that contain either a photodiode or a thermal sensor, as well as power meter bundles that include a console, sensor head, and post mounting accessories.

Thorlabs offers four types of sensors:

- Photodiode Sensors: These sensors are designed for power measurements of monochromatic or near-monochromatic sources, as they have a wavelength dependent responsivity. These sensors deliver a current that depends on the input optical power and the wavelength. The current is fed into a transimpedance amplifier, which outputs a voltage proportional to the input current.

- Thermal Sensors: Constructed from material with a relatively flat response function across a wide range of wavelengths, these thermopile sensors are suitable for power measurements of broadband sources such as LEDs and SLDs. Thermal sensors deliver a voltage proportional to the input optical power.

- Thermal Position & Power Sensors: These sensors incorporate four thermopiles arranged as quadrants of a square. By comparing the voltage output from each quadrant, the unit calculates the beam's position.

- Pyroelectric Energy Sensors: Our pyroelectric sensors produce an output voltage through the pyroelectric effect and are suitable for measuring pulsed sources, with a repetition rate limited by the time constant of the detector. These sensors will output a peak voltage proportional to the incident pulse energy.

| Console Compatibility | ||||||||

|---|---|---|---|---|---|---|---|---|

| Console Item # | PM100A | PM100D | PM400 | PM5020 | PM101 Series |

PM102 Series |

PM103 Series |

PM100USB |

| Photodiode Power |  |

|

|

|

|

- |  |

|

| Thermal Power |  |

|

|

|

|

|

- |  |

| Thermal Position | - | - |  |

|

- |  |

- | - |

| Pyroelectric Energy | - |  a a |

a a |

|

- | - |  |

a a |

Power and Energy Sensor Selection Guide

There are two options for comparing the specifications of our Power and Energy Sensors. The expandable table below sorts our sensors by type (e.g., photodiode, thermal, or pyroelectric) and provides key specifications.

Alternatively, the selection guide graphic further below arranges our entire selection of photodiode and thermal power sensors by wavelength (left) or optical power range (right). Each box contains the item # and specified range of the sensor. These graphs allow for easy identification of the sensor heads available for a specific wavelength or power range.

| Photodiode Power Sensors |

|---|

| Thermal Power Sensors |

|---|

| Thermal Position & Power Sensors |

|---|

| Pyroelectric Energy Sensors |

|---|

Sensor Options

(Arranged by Wavelength Range)

Sensor Options

(Arranged by Power Range)

| Posted Comments: | |

Shu Wang

(posted 2024-10-18 18:00:54.877) Hi our power meter console PM100D cannot be turned on occasionally. We charged it with enough battery. Could you help with some suggestions to solve the problem? Thanks! hkarpenko

(posted 2024-10-21 08:23:49.0) Dear customer,

thank you for your feedback. I will contact you directly to discuss this issue with you. Riku Hayakuni

(posted 2024-10-16 14:40:22.743) Q.シリアル通信用のポート識別ドライバーはどれでしょうか。

PCからPM100Dへコマンドを送信してデータを取得するプログラムを自社で作成したいと思っております。

ポート番号を指定してVBAで通信したいのです。

デバイスマネージャー上でUSBは認識しているのですが、ポートとして認識されません。

専用のソフトウェアではリモート接続できておりコマンドを通信は行えます。 GBoedecker

(posted 2024-10-16 11:25:05.0) Thank you for your feedback! The powermeter does not have a port number. I will contact you directly to discuss possible solutions. user

(posted 2024-09-23 15:03:37.093) We've had one of these meters for about a year, and it seems to be having trouble holding a charge. Is it possible to replace the battery? Also, does thorlabs sell a spare power supply? jjadvani

(posted 2024-10-01 05:06:39.0) Dear Peterm, Thank you for providing feedback. Yes, it is feasible to replace the battery at our location. You can also buy the power supply separately. I will contact you directly to offer further assistance. Emma Condon

(posted 2024-09-06 12:44:46.23) Dear Thorlabs,

I am receving the following error, which shows when the device (PM100D) is turned on: 'Error 0x000000B9 Timeout during SD-card communication'. I have two questions: (1) does this error affect the readout? (2) How can this error be resolved?

Many thanks jjadvani

(posted 2024-09-09 06:32:32.0) Dear Emma, Thank you for your feedback. I will contact you directly to troubleshoot your issue. Binjie Zhang

(posted 2024-09-02 06:46:51.093) My PM100D screen becomes blank after booting up, is there any solution to this? Jacob Murphy

(posted 2024-08-20 07:57:28.39) Hi there, what material is the red soft case made out of for the PM100D? I think it might be silicone. Thank you Jake hchow

(posted 2024-08-20 05:01:37.0) Dear Mr. Murphy, thank you for your feedback. You are indeed correct, the red sleeve around the PM100D is made of silicon rubber. Lin Zhou

(posted 2024-06-14 13:38:46.49) I am using different range of PM100D to record output voltages and it seems the responsivities of different ranges are different. For example, when I'm detecting the same light , working in range 960nw gives me a voltage of 1.8V while woring in range 9600nw giving 0.24V. This relationship doesn't seem clear and I haven't seen anything about this relationship in the PM100D documents. hchow

(posted 2024-07-18 08:17:06.0) Dear Mr. Zhou, thank you for your feedback.

Your question is multi-faceted and too complex for me to give you a proper response here. I will personally reach out to you to provide a comprehensive solution. Thank you. Won-il Lee

(posted 2024-04-30 13:38:52.207) Can I buy only the power meter charger separately? jjadvani

(posted 2024-04-30 03:17:49.0) Dear Won, thank you for contacting Thorlabs. Yes, you can purchase power supply separately. I will contact you directly to provide information on how you can purchase a power supply. jjadvani

(posted 2024-04-30 03:17:49.0) Dear Won, thank you for contacting Thorlabs. Yes, you can purchase power supply separately. I will contact you directly to provide information on how you can purchase a power supply. user

(posted 2024-04-04 09:59:36.527) The battery for my PM100D does not hold charge anymore. Rather than buying a new device, can I replace just the battery? If so, how do I go about that? hchow

(posted 2024-04-04 10:26:34.0) Dear User, thank you for your feedback. If your PM100D's battery is faulty or not chargning or does not hold a charge any longer, we highly recommend you sending in your device for a battery repair/exchange. Thank you. user

(posted 2024-02-05 07:47:19.54) I use PM100D and an S122C head to measure light intensity spectra at the monochromator output. The system is controlled by a program written in LabView. The light intensity is modulated by the chopper in the range of 10Hz -300Hz. When I work in auto range mode and the light intensity increases monotonically, at some point the measured light intensity decreases. This appears when the measured value is close to the maximum value of the range. I did an experiment at one wavelength W=950nm. When I set the range to 1.5mW I got an optical power of 0.253 mW. After changing to auto range I received the same P=0.253 mW. When I set the ranhe to150 mW I got 109.5 uW, after changing to auto range the same 109.5 uW. I set the Range to 13 uW and received HIGH, and after changing to auto range it was 109.5 uW. Why doesn't the meter switch to a higher range? Thank you. dpossin

(posted 2024-02-07 08:33:40.0) Dear customer,

Thank you for your feedback. I´ll reach out to you in order to provide assistance. Genshiro Sunagawa

(posted 2023-12-30 15:59:38.75) I am using PM100D + S150C to detect the light from LED M385F1. When I try to set the wavelength of PM100D to 380 nm, it says, "The adjusted wavelength is outside the sensors wavelength range". Indeed, the sensor info page displays that S150C's wavelength range is 400nm-1100nm, which does not match the spec of S150C. How can I set the wavelength to below 400nm? Thank you. dpossin

(posted 2024-01-02 09:17:07.0) Dear Genshiro,

Thank you for your feedback. This sounds like a malfunction since the sensor is specified to be sensitive down to 350nm. I am reaching out to you in order to provide more detailed assistance. 敏洁 李

(posted 2023-12-30 12:00:44.03) 充电时,充电接口位置有烧糊的味道,且电量显示位置显示箭头,这是什么原因导致的?应该怎么维修处理? hkarpenko

(posted 2024-01-03 06:22:53.0) Dear customer,

thank you for your feedback. It seems that the console is in need of repair. Thus we will directly contact you to guide you through our RMA process. user

(posted 2023-12-27 18:48:14.04) Hi, I use PM100D and S121C to measure laser power at around 80 uW. I use OPM software to control and record data. The recording frequency is around 200 datas per second. BUT the data oscillates up and down at around 100Hz over a 3uW range. Is there an explanation? dpossin

(posted 2024-01-02 09:45:57.0) Dear customer,

Thank you for your feedback. I reach out to you in order to provide assistance. Chia-Lun Tsai

(posted 2023-12-21 18:02:54.823) We have got voltage values, and we want to chane voltage to power. Is there a table for voltage to power? dpossin

(posted 2023-12-27 08:00:40.0) Dear Chia-Lun,

Thank you for your inquiry. I reach out to you directly in order to clarify your questions. Peng Zhao

(posted 2023-12-06 09:57:40.94) Hi,

i have PM100D power meter and S130C detector,

both seems have a problem, PM100D always display 0 and zero! warning, S130C detector can't be recognized by the power meter.

can you fix them?

please give a RMA number

thank you hkarpenko

(posted 2023-12-07 10:27:45.0) Dear customer,

thank you for your feedback. These errors indicate, that either the console or the sensor are in need of a repair. I will contact you directly to discuss this further with you in detail. Sam Chen

(posted 2023-10-10 11:19:21.28) When I use PM100D&S150C to detect the LED power of nW level, the measurement View is set to Numeric, but the display only shows one digit after the decimal point. like 0.7nW. How do I set it to display more valid digits at the Numeric view? jweimar

(posted 2023-10-16 07:07:02.0) Thank you for your feedback! Unfortunately, the 4 digits of PM100D display are not configurable. The highest resolution is 100pW. If you need a higher resolution, you can connect the device to your computer and use the “OPM” Software or use the statistics screen in the device. Jean-Jacques HONORINE

(posted 2023-10-02 09:22:23.07) Dear,

My OS: Windows 2020.

My Labviews version: Lab 2014.

dfu file: PM100D_V2.8.1.dfu

I can't install "PM100D_V2.8.1.dfu", it's normal?

Message: No devices found. Verify if device is connected or if you select the right.dfu file. GBoedecker

(posted 2023-10-05 06:20:38.0) Thank you for your feedback! Please check the current firmware version. If you already have version 2.8.1, you can get this error message. GBoedecker

(posted 2023-10-05 10:32:57.0) Choose "Enable" on the console in System Menu\Console Settings\Firmware Update\ to enable the firmware update. user

(posted 2023-08-21 01:18:16.437) Where can i find the driver of this instrument?

I have downloaded the software given above, but its not working.

I would be extremely grateful if you could provide me a direct link of the driver . I have to connect it to LabView program and do my project!

Thank you! hkarpenko

(posted 2023-08-21 11:18:55.0) Dear customer,

thank you for your feedback. If you are looking for the software of the PM320E, you might have downloaded the wrong software. I will contact you directly and share the correct software with you. Ben Sauer

(posted 2023-06-01 13:33:42.077) We have several PM100's in out lab. They have a common failure mode which could be improved by a design change. The problem is that the d-sub 9 connector for the sensor is a surface mount connector. When someone drops the meter the sensor connector tends to break the SMT bonds to the main circuit board. Sometimes this is repairable and sometimes it isn't. In your next design iteration you should change this connector to a through hole one, which would be much more robust.

Do you sell the main pcb for this as a replacement part? It's model number is M0094-222-800. hchow

(posted 2023-06-01 11:20:45.0) Dear Ben, thank you for your feedback. We do take interest in what our customers have to say about our products. And any feedback you can provide us is valuable. As for the second part of your question, I will personally reach out to you to provide a solution. Thank you. wang jing

(posted 2023-05-22 18:51:23.067) 请问功率计如果想要测试一个波段范围内的平均功率应该怎么设置?可以测多个波长的激光平均功率吗? hchow

(posted 2023-05-24 05:36:57.0) Dear Wang Jing, thank you for your feedback. If you would like to measure the optical power of multiple wavelengths, you would have to set the wavelength setting on the PM100D each time to the preferred wavelength you want to measure. The PM100D is not able to measure the optical power from multiple wavelengths at a time. I will personally reach out to you to provide more information. Thank you. Taeho Woo

(posted 2023-03-22 22:55:07.36) Hi

Would it be possible for me to ask a question?

I was wondering if you could provide me with some information about the temperature levels that the equipment recognizes when it is subjected to different power inputs, specifically 1mW, 2mW, and 3mW. Additionally, would it be possible for me to request a graph that shows the relationship between temperature and power?

I would greatly appreciate any assistance you can offer. Thank you very much. dpossin

(posted 2023-03-28 05:35:38.0) Dear Taeho Woo,

Thank you for your feedback. I am reaching out to you directly to discuss this in more detail. Carlo Ferrari

(posted 2022-11-27 23:23:11.867) Hello, I would like to purchase a replacement power cable for this device. I wasn't able to find it anywhere on the product page or the site.

Can you send me a quote, pleae.

Best regards,

Carlo fmortaheb

(posted 2022-11-28 04:47:14.0) Thank you very much for contacting Thorlabs! We will reach out to you directly and provide you with a quote. Karl Ahrendsen

(posted 2022-10-05 11:44:14.31) Where can I purchase a replacement power cable for this device? I wasn't able to find it anywhere on the product page or the site. fmortaheb

(posted 2022-10-06 05:24:27.0) Thank you very much for contacting us. We will contact you directly to provide you with a quote for the power supply. Igor Musevic

(posted 2022-09-20 12:34:34.29) Hello,

We have PM100D Power meter with S121C, S120C and S470C sensors. We would like to measure the single pulse energy from a 120 fs tunable laser ORIGAMI XP. The repetition rate of this laser can be adjusted from 1 Hz up to 100 kHz. The idea is to measure the average power and divide it by the rate of pulses.

In the manual, there is little information on the frequency range of PM100D. It is only mentioned that it can measure average power of pulsed lasers up to 100 kHz.

Could you please advise us on the optimum repetition rates of our laser to best suit frequency range of PM100D.

What setting of PM100D should be used with that selected repetition rate?

Thank

You

Igor Musevic, Head of the Lab. hkarpenko

(posted 2022-09-22 05:09:24.0) Dear Igor,

thank you very much for your feedback. For these short pulses it´s better to use the thermal based sensor instead of the photodiode one.

I will contact you directly to discuss this case further with you. Laurent Mercadier

(posted 2022-09-09 08:39:37.977) Dear Thorlabs,

I am regularly using a PM100D for laser power measurement. While it works well, I would like to suggest an improvement:

Changing the role of the wavelength button to the role of zeroing.

The reason is that when measuring a laser power, the wavelength is set and there is no need for a convenience button, however we often need to calibrate the detector to zero, especially with low powers. In statistics mode, the only way to do it is to break from statistics to numeric, then navigate another menu to finally be able to press zero. Then, we need to navigate back to statistics, which is tedious and time consuming.

Would it be possible to consider this for a firmware update and exchange the role of the wavelength button to zeroing button?

Thanks in advance,

Dr. Laurent Mercadier fmortaheb

(posted 2022-09-12 10:38:31.0) Thank you very much for your feedback. We don't have any plan to modify the front panel in the near future, but we will consider your suggestions. Concerning the zeroing, it should be possible to do it without switching between the screens. I'll reach out to you directly to discuss it further. Davide Michele Stefano Marcolongo

(posted 2022-05-12 15:16:21.29) Recently, I used a PM100D Console equipped with a S120VC sensor to try the measure of output power of an old short-arc Xe lamp (150 W nominal electrical power) and of some commercial indoor light white LED sources. The console+sensor are not my property, but I found that all the measured sources have an emission output extremely shifted into the UV region and emit quite no power in long visible wavelenght range (red). The same was found with a red LED commercial pointer. Should I consider the instrument is out of calibration?

Thanks in advance

Dr. Davide M.S. Marcolongo mdiekmann

(posted 2022-05-17 03:05:51.0) Thank you for contacting us! We will email you directly to troubleshoot this application. Possible issues in this case could be setting the right measurement wavelength given the broad spectrum of the light sources and the angle of incidence. If the unit has not been calibrated recently, that could also cause incorrect readings. Xu Yan

(posted 2022-04-20 02:07:18.4) Hello I'm having Error 0x000000B9 "Timeout during SD-card communication". There is any possible solution to this? fmortaheb

(posted 2022-04-25 12:13:57.0) Dear Xu Yan, Thank you very much for your feedback. I'll contact you directly for troubleshooting. 李 彥澄

(posted 2022-03-01 02:50:35.907) when I used c# to get the laser(senter wavelength :1024nm)power by PM100D,c# may get wrong power value.especially after I use this driver:(https://www.newport.com/p/8742) 8742motion controller to move pezio mirrors,the mirrors move every 0.1 second,mirrors moving will chenge the power of laser.after moving,c# usually get wrong power from PM100D,for example,I saw the PM100D show power is 100mW,but c# get 50mW.

What can I do to get the currect power by c#?whith is the real power?power witch PM100D showed or power witch readed by c#? is it possible to let power showed by PM100D and power readed by c# alway be the same,at any time?

thank for you reply. wskopalik

(posted 2022-03-02 03:55:15.0) Thank you for your feedback!

The power values shown on the PM100D and in C# are the same if the same settings are used. The most important setting is usually the wavelength. You can use the “setWavelength” function to adjust the wavelength in C#. If you e.g. use an attenuation setting or a particular power range on the PM100D, these settings would need to be made in C# as well to get the same results.

I will contact you directly to provide further assistance. Carlos Reyes

(posted 2022-02-07 12:24:34.873) Hello,

I have recently bought a PM100D. I downloaded the most recent sw and I was able to connect to it using the application.

When trying to control the power meter using LabView the Visa Driver is not recognized. The device appears in the device monitor but not in Ni-Max. I tried installing the legacy versions and still was unable to make a successful connection. I'm currently using LabView 21.0. Could you reach for further support? wskopalik

(posted 2022-02-10 03:16:25.0) Thank you for your feedback!

There are two different drivers available for the PM100D. The older PM100D driver was using the NI-VISA interface. The new TLPM driver is no longer using this interface. They can however both be used in LabView by using the provided VIs.

You can use the “Power Meter Driver Switcher” tool which is installed with the “Optical Power Monitor” software to switch between the two drivers. This can e.g. be helpful if you already have an application which is using the older driver.

I will contact you directly to provide further assistance. Patrick Schmidt

(posted 2022-01-04 18:29:34.687) I have a PM100D and S175C for power measurement. I would like to collect and log data in Python on a windows PC, do you have a clean way to do this? Thanks. GBoedecker

(posted 2022-01-07 10:53:33.0) Dear Patrick, thank you for your inquiry. We provide a Python wrapper for the instrument driver. After installation of the software, you find the wrapper, the manual and a Python example in the folders documented in chapter 9 of the software manual.

https://www.thorlabs.com/software/MUC/OPM/v3.0/TL_OPM_V3.0_web-secured.pdf Borislav Glebov

(posted 2021-10-21 11:53:34.85) Hello. A few years ago I used the PM100-D device and a very old version of the Optical Power Monitor. The software had a feature - the number of recorded points is no more than 3000. Therefore, at high time resolution, it could record data for no more than 30 seconds. Now we can use Optical Power Monitor v3.1 for PM100-D, and there is no parameter "number of recorded points" in it, but the "resolution" tab remains. Does this mean that the limit on the number of recorded points at any resolution has now been removed for PM100-D and is limited only by the free space of the PC RAM? In other words, is it now possible to record data from PM100-D for several hours with a resolution of 0.01 seconds? dpossin

(posted 2021-10-27 12:18:51.0) Dear Borislav,

Thank you for your feedback. Its right, that there is no limitation regarding the maximum number of data points. However the data acquisition rate is fixed to 300ms and can´t be changed. The values are then saved to the included SD card which allows recording duration of several hours. I am reaching out to you in order to discuss this matter more detailed. dpossin

(posted 2021-10-27 12:18:51.0) Dear Borislav,

Thank you for your feedback. Its right, that there is no limitation regarding the maximum number of data points. However the data acquisition rate is fixed to 300ms and can´t be changed. The values are then saved to the included SD card which allows recording duration of several hours. I am reaching out to you in order to discuss this matter more detailed. Mike Sym

(posted 2021-10-20 08:15:14.197) Hello, regarding the measurement range, the manual states that the measurement will be precise within -10% to 110% of the selected range. If the range is set to eg. 10mW, this means that the values are precise within the [9,11] mW range, right? Can the measurement range be set manually in some arbitrary value within the range of the sensor?

To better explain my question, I am monitoring the power-meter output from the analog interface, however when the power reaches ~12mW, the range is increased by a factor of "10" and the output get very noisy (as it lies now close to the "0" level). So, I would like to set the range at about 20mW.

Thanks! dpossin

(posted 2021-10-26 03:57:34.0) Dear Mike,

Thank you for your feedback. The autoranging can be disabled but the range limits can´t be changed as they are determined by the current measurement bridge on the hardware. I am reaching out to you to provide further information. Mike Sym

(posted 2021-10-15 14:51:22.13) Hello, is there a way to control the power meter or extract the CSV files using a Linux distribution? That would be really helpful. dpossin

(posted 2021-10-25 10:22:55.0) Dear Mike,

Thank you for your feedback. Well we also provide a Linux (Ubuntu) version of our optical power monitor software on request. I am reaching out in order to provide it to you. Vad Kir

(posted 2021-06-30 05:13:52.687) Hello I'm having Error 0x000000BE "Invalid directory name". There is any possible solution to this? MKiess

(posted 2021-07-05 08:31:25.0) Dear Vad, Thank you very much for reporting this issue. I will contact you directly for troubleshooting. J Schmoll

(posted 2021-06-10 14:32:34.813) I tried testing the PM100D using the LabVIEW examples supplied with the Optical Power Monitor software. The LabVIEW VIs are in the TLPM.LLB file. I tried to run the 32-bit examples. However, the example VI "Measure Power Sample.vi" was apparently saved in LabVIEW version 2019. I was trying to run the VIs in LabVIEW 2017. All of the other VIs in the library were apparently saved with earlier versions of LabVIEW, and I could open them without problems.

I have used other Thor optical power meters in LabVIEW, so I wrote a simple test program using the same VI calls that worked for the other power meters. The code failed in the initialization step. The PM100D had firmware version 1.3.1. I updated it to 2.7.0, and now my LabVIEW code runs without error. MKiess

(posted 2021-06-14 09:56:12.0) Dear Mr. Schmoll, Thank you very much for this feedback. The version 1.3.1 is a quite old firmware version, with which there can be complications with the newer drivers. An update to the latest firmware and software version is always a recommendation here. Milan Delor

(posted 2021-03-11 19:01:51.41) Hello, are your power meter consoles (PM100D or PM400) compatible with power sensors from other manufacturers, such as Coherent? Alternatively, do you make custom power sensors? We need a 40 - 50 W max power sensor which is unfortunately not available with Thorlabs. soswald

(posted 2021-03-16 10:55:31.0) Dear Milan,

thank you for your feedback. Our power meter consoles are not compatible with third-party sensors.

For high powers in the 40-50 W regime we offer thermal sensors such as S425C-L or S322C. Since you prefer not to be contacted, please reach out to your local tech support team directly to discuss your application in more detail. MKiess

(posted 2020-12-14 06:34:06.0) Thank you for your feedback. Please check that you have the latest firmware installed on the PM100D. We have made a few changes regarding the SD card. You can find the firmware download at the link below:

https://www.thorlabs.de/software_pages/ViewSoftwarePage.cfm?Code=OPM user

(posted 2020-11-18 12:44:15.56) Is there a way to reset all settings/memory to the factory default? MKiess

(posted 2020-11-19 09:58:02.0) Thank you very much for your inquiry. Depending on the sensor used, the PM100D can be reset to the default settings for the respective sensors (thermopile, photodiodes, pyroelectric). This can be done under 'System Menu \ Measurement Settings' for the corresponding sensor. Alexander Kuznetsov

(posted 2020-06-30 10:25:33.08) I have a question about the drivers TLPM_32 and PM100D_32.

In our lab, we have a custom software to communicate with several PM100D remotely (e.g. the PM100D is connected to one PC and a user communicates with it from another PC). Such remote communication using PM100D_32.dll via NI-Visa Server works fine. However, devices configured to use the TLPM_32.dll driver are not "visible". Switching the driver to PM100D_32.dll solves it. However I would like to know, how would one achieve the remote communication with the device using TLPM_32.dll?

Thank you in advance. dpossin

(posted 2020-07-03 03:53:47.0) Dear Alexander,

Thank you for your feedback. We switched our software from the NI-VISA based driver PM100D.dll to the more robust driver architecture TLPM.dll. However if you need the old driver for your application we provide a tool called power meter driver switcher is installed together with the power meter software. Please find instructions how to change between the drivers in section 7 here: https://www.thorlabs.com/software/MUC/OPM/v2.2/TL_OPM_V2.2_web-secured.pdf. Also the commands are different compared to the old NI-VISA based driver. Instructions on programming the TLPM driver can be found here: C:\Program Files (x86)\IVI Foundation\VISA\WinNT\TLPM\Manual. I am reaching out to you in order to provide further support. BINBIN ZHAO

(posted 2020-05-04 01:29:02.887) Is there any example of MATLAB code used to control the PM100D and record the power automatically? MKiess

(posted 2020-05-05 10:38:32.0) This is an response from Michael of Thorlabs. Thank you very much for your inquiry. I have contacted you directly to provide further information. Yangyang Liu

(posted 2020-01-09 15:12:26.583) I am using PM100D. Recently, I want to update the firmware. And I connect the PM100D to computer by the monitor software. When I use the software to update the firmware there is always a warning that "user abort the download operation" but I do nothing. Hope for your answer. Thanks. Regards, Yangyang Liu. nreusch

(posted 2020-01-10 08:52:49.0) This is a response from Nicola at Thorlabs. Thank you for contacting us. Could you please check whether you enabled the firmware download mode on the PM100D console (System Menu -->

Console Settings -->

Firmware Upload -->

Enabled) before trying to install the new firmware with the DFU wizard? A local Tech Support representative will contact you for further troubleshooting. Junji Okamoto

(posted 2019-12-12 09:13:59.773) I would like to know about "analog output" of PM100D.

Q1, Is the output voltage from analog output "DC" voltage? (Is its wave shape flat?)

Q2, Is the output voltage basically go from 0V to +2.0V? (In a Manual, from -0.3V to +2.3V) wskopalik

(posted 2019-12-12 11:13:29.0) This is a response from Wolfgang at Thorlabs. Thank you for your inquiry!

The voltage signal at the analog output is the amplified photo-diode current or the amplified thermal or pyroelectric sensor voltage. So the voltage will change corresponding to the power of the incident light. If the incident light is CW, the signal will be a flat voltage signal. If the incident light is however modulated or pulsed, the signal will be modulated or pulsed as well.

The range of 0V to 2V is the range in which you will get reliable measurement results. If e.g. the amplifier or the sensor are saturated, it is however possible that you get voltages in the range of -0.3V up to +2.3V. So the devices attached to the analog output should be able to handle voltages in this range without any damage.

I will contact you directly to provide further assistance. A. Devine

(posted 2019-12-02 15:49:34.81) While polling a thermopile sensor over USB with the PM100D (using the LabVIEW drivers), occasionally NaN is returned instead of an actual power reading value. This seems to happen most frequently when readings are taken too close together. I have solved the problem by adding a 20 second delay between readings, but this seems too large. I do not experience the same behavior with the PM200 or newer power meters. I would appreciate any insight as to why the meter is returning NaN so that I can work on a more elegant solution.

Thanks,

AD MKiess

(posted 2019-12-05 09:32:58.0) This is an response from Michael of Thorlabs. Thank you very much for your inquiry. I have contacted you directly to discuss the specifications and measurement procedure of your light source, as well as the programming to find a solution together. Ian Roberts

(posted 2019-10-29 19:32:01.613) Using the SCPI commands in the manual I can communicate with the PM100D over USB to read the instantaneous power, which works well. However, I want to record data at a high rate (ideally every millisecond) which is too fast for serially polling the device using the MEAS power command.

As the device can make measurements very rapidly and store the data to a CSV file, is it possible to read this data / transfer the file (once measurement is finished) over USB using SCPI commands? Or some other way (e.g. mounting the storage as a device the computer can access?)

I appreciate Thorlabs offer a driver package / GUI but having to install separate software is highly unattractive (/ not even possible in some situations due to lack of admin rights). Thanks. MKiess

(posted 2019-10-31 08:55:39.0) This is a response from Michael at Thorlabs. Thank you very much for the inquiry. The limitation here is due to the data transfer rate of USB. However, you can use the analog output, which has a bandwidth of up to 100kHz. I contacted you directly to find a suitable solution for your application together. DAVID KINGHORN

(posted 2019-06-07 20:44:24.12) What is the part number for the AC Battery Charger for the PM100D Console? MKiess

(posted 2019-06-12 05:05:45.0) This is a response from Michael at Thorlabs. Thank you very much for the inquiry. The AC adapter for charging the system battery is not a standard Thorlabs product and therefore not available on our website. But of course it is possible to get a replacement from us. I will contact you directly to discuss further steps. Samuel Gyger

(posted 2019-05-31 05:55:41.643) We have the devices for a long time now and it seems the battery becomes bad (S/N P0000874) and (S/N PM001464)

Is it possible to exchange the battery by ourselves. Are you selling replacement batteries? Or should we buy one online?

Regards,

Samuel Gyger dpossin

(posted 2019-06-06 09:56:01.0) Thank you for your feedback. It is not intended to change the battery by our customers but we offer to change the battery inhouse as a service. I will reach out to you directly in order to discuss the details. Eneko Lopez

(posted 2019-03-21 07:29:41.42) we have a PM100D console with a S121C sensor. Is there anyway to acquire data with matlab software? It would be very helpful for us.

Thank you! swick

(posted 2019-03-29 04:40:11.0) This is a response from Sebastian at Thorlabs. Thank you for the inquiry. It is possible to remote control our power meter via Matlab. I contacted you directly to provide assistance. Cao Duc

(posted 2019-03-21 10:37:56.82) we recently received the PM100D console and a pyroelectric energy sensor ES120C with accessories. I tried to connect the sensor and the console by the insulator, post, and post holder but there was no signal at the display of the console, although it recognized the sensor, i turned trigger number down to 3%, then when i touched the console or the sensor it started having some noise, but the noise also stopped when i stopped touching. I tried again with my laser source, there was signal again. Can you give me some advice; or the specific connecting or setting guide of those devices will be very helpful with me. Thanks you! swick

(posted 2019-03-29 04:57:09.0) This is a response from Sebastian at Thorlabs. Thank you for the inquiry.

The function principle for these sensors is different compared to Thermopiles or Photodiodes. Pyroelectric sensors (ES-Series) do only generate a signal when an optical pulse is detected.

The pulse energy needs to be larger than the threshold which is defined via trigger level thus when setting trigger level to very low values you can observe noise. The measurement value will be updated with each incoming pulse and when no pulses appear the measurement display will be held on the last measured value.

I contacted you directly to provide further assistance. jagroopastro5

(posted 2019-01-05 22:00:31.453) sir,

recently i have purchased the PM100D with S130VC sensor module. i have measured the He Ne laser power with it and same time corresponding current in current mode. when i compare with the response curve of the sensor, it is showing high responsivity ( 0.4 approx against 0.36 specified value and it varying non linearly with power? why it is so?

sir, do a high frequency oscillator device placed near sensor hear will affect the measurement of device? wskopalik

(posted 2019-01-08 07:30:13.0) This is a response from Wolfgang at Thorlabs. Thank you very much for your feedback!

There are different possible reasons for this, e.g. the coupling of the laser in the sensor, incorrect settings on the power meter or also tolerances in the power of the laser itself.

I will contact you directly so we can look into the details and find an explanation for these results. krzysztof.anders

(posted 2018-12-14 21:06:32.34) After deleting all files and directories on SD card I'm unable to write statistics file - every time I get Error 0x000000BE "Invalid directory name". I was trying also to format SD card (FAT32) and putting there PM100LOG directory - still the same problem nreusch

(posted 2018-12-20 07:28:56.0) This is a response from Nicola at Thorlabs. Thank you very much for reporting this issue. I will contact you directly for troubleshooting. jlm

(posted 2018-10-01 14:17:08.03) Hey

I am trying to interface to your console PM100D with a c++ program written in QT.

In the document https://www.thorlabs.com/software/MUC/OPM/v1.1/TL_OPM_V1.1_web-secured.pdf you state that I should find a header file at;

“C:\Program Files (x86)\IVI Foundation\VISA\WinNT\include\TLPM.h”

Unfortunately I cannot locate such a file. I tried to repair the installation, but that did not mend the issue.

Can you help me? nreusch

(posted 2018-10-04 04:58:17.0) This is a response from Nicola at Thorlabs. Thank you for your inquiry. Yes, you are right the header file should be stored there. As this does not seem to be the case, I will send you the file via email. kay.schaarschmidt

(posted 2018-08-08 15:23:22.83) Hi,

we are trzing to use the Thorlabs software and labview to read out data from a PM100D. It worked for occasionally but suddenly an error kept occuring

Error -1073807345 occurred at PM100D Initialize.vi

Neither our self-made labview program, nor the Thorlabs software is currently working anymore.

Help appreciated. nreusch

(posted 2018-08-09 10:59:53.0) This is a response from Nicola at Thorlabs. Thank you for your inquiry! This seems to be a connection issue. I recommend to start troubleshooting this by using the Thorlabs software. Which version is installed on your PC? I will contact you directly to provide further assistance. user

(posted 2018-06-20 13:03:01.267) The cable on the wand is quite annoying. Will you ever offer a wireless sensor? YLohia

(posted 2018-06-20 04:26:31.0) We offer wireless sensors here: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=7233 hi243

(posted 2018-06-09 19:50:50.447) Hi,

I have the PL450B blue laser diode (450nm, 80mW) and I wish to measure the optical power coming out of this laser diode when it is pulsed at 30mW. The laser beam will be obstructed by a tuning fork element I am using, so the final optical power that I need to detect is around 1mW. My lab already has the PM100D console, so I just need help from you on deciding on a suitable power sensor/photo diode which can help me measure optical powers in the range 1mW-80mW (@450nm). Thanks mvonsivers

(posted 2018-06-13 09:03:15.0) This is a response from Moritz at Thorlabs. Thank you for your inquiry. The S121C would be suitable to measure powers of 500 nW - 500 mW in the wavelength range 400 - 1100 nm. Please note that for the measurement of pulsed sources special considerations have to be taken into account. I will contact you directly for further discussion. magnus.engholm

(posted 2018-03-26 09:49:29.23) Hi, We have the PM100D console and several photodiode and thermal sensors. Now, we are interested to measure the energy from a Xenon flash tube, hence a single pulse measurment. Can you please advice if/how this can be performed with the PM100D and what sensor neded? swick

(posted 2018-03-28 04:15:29.0) This is a response from Sebastian at Thorlabs. Thank you for the inquiry.

We recommend pyroelectric sensors for single pulse energy measurements. It depends on several optical parameters (pulse width, average power, beam diameter, repetition rate) if these sensors are suitable for your light source. I contacted you directly for assistance. pier29

(posted 2018-03-05 03:34:23.977) And I also want to know whether the device (S/N P0005229) is compatible with S120VC or not.

Spec. information says that "For the S120VC, these specifications are valid for devices with serial numbers 1203xxx or higher." wskopalik

(posted 2018-03-05 08:06:34.0) This is a response from Wolfgang at Thorlabs. Thank you very much for your inquiry!

Yes, the PM100D is compatible with the sensor S175C, S120VC and all other currently offered power meter sensors. The information you have found on the website for the S120VC is only concerning the specifications we give for this sensor, but not the compatibility. The specifications have changed a while ago, so for sensors with serial numbers lower than 1203xxx they are slightly different.

I will contact you directly to provide further assistance. pier29

(posted 2018-03-05 03:28:17.093) Hi, I already have PM100D (with S122C) and its serial number is P0005229. Is this device compatible with S175C?

Thank you. wskopalik

(posted 2018-03-06 09:17:38.0) This is a response from Wolfgang at Thorlabs. Thank you very much for your inquiry!

Yes, the PM100D is compatible with the sensor S175C and all other currently offered power meter sensors.

I will contact you directly to provide further assistance. louis_declerck

(posted 2017-12-08 19:13:13.053) Hi,

I am currently working with a spectrometer and the optical powermeter PM100A from thorlabs. My question to you guys is how the powermeter calculates the optical power from W into W/cm². Which area is chosen therefore? Another question is how the optical power is calculated itself. Is that done by a sort of integration over a range of wavelengths around the 'preferred wavelength' in the settings?

This is very important for me since the data from a spectroscope are not corresponding to data from the PM100A.

Sincerely yours,

Dr Louis Declerck swick

(posted 2017-12-18 03:41:00.0) This is a response from Sebastian at Thorlabs. Thank you for the inquiry.

PM100A can not display power densities so I think this is about PM100D. To display the power density in W/cm² in the right sub display it is necessary to enter the diameter of the incident beam or at an overfilled sensor the diameter of the sensor aperture. In the Meas Config menu the beam diameter can be set. I have contacted you directly for further assistance. lokirune

(posted 2017-11-08 00:29:25.34) Hi. I just lost power supply for PM100D. Where can I get them ? Thanks. mdiekmann

(posted 2017-11-10 06:23:27.0) This is a response from Meike at Thorlabs: Thank you for contacting us! We will get in touch with you directly to provide a quote for the power supply. aye.aung

(posted 2017-10-04 23:04:07.507) Dear Sir/Mdm,

We are using PM100D to measure optical power of LEDs. The wavelength of LED is 850 nm. The sensor that we used is S120C which can measure from 400nm-1100nm. We set 850 nm at PM100D and get measurement. We also tried to set various wavelengths (400, 500,.., 1000, 1100 nm and so on) and get measurements. It is observed that the peak power is occurred to be at 1100 nm and the power at 850nm is lower than most of the measurement powers at other wavelengths. Please kindly advise. Appreciate if you could contact us. Thanks. wskopalik

(posted 2017-10-05 04:54:48.0) This is a response from Wolfgang at Thorlabs. Thank you very much for your inquiry.

The wavelength you enter on the PM100D determines which responsivity is used to convert the current coming from the photodiode into a power values. This is necessary due to the spectral dependence of the responsivity of photodiodes. The sensor itself can however only measure the total power of a beam and cannot separate different wavelengths. This can lead to inaccuracies when you measure LEDs with a wide spectral distribution, because some parts of the spectrum may not be converted with the correct responsivity.

The difference in the results you see is basically the spectral dependence of the responsivity of the sensor. The responsivity is quite low around 400nm and 1100nm, in between it increases to a maximum at around 950nm - 1000nm. You should see the inverse of that in the power values when you change the wavelength which agrees with what you have seen.

I have contacted you directly to discuss all this in more detail. DingR.F.1987

(posted 2017-04-05 17:06:16.62) We would like to use S130vc & PM100D for measuring laser power. And we want to connect PM100D to NB via USB. Thus, what is the range of sampling rate will we obtain? Could we adjust it? Thank you. swick

(posted 2017-04-06 03:13:43.0) This is a response from Sebastian at Thorlabs. Thank you for the inquiry.

In Thorlabs Optical Power Meter Utility at "Log Config" you can adjust the Number of Samples, the Interval Time (min. 0.1s) and the Averaging. Via Labview the max. sampling rate would be 300Hz. abyangphilip

(posted 2017-03-02 20:40:14.097) I'm using your device PM100D. Just now the power meter can't read anything from the sensor and displayed Zero. It can read when I press the connector to the power meter with much strength. But it just can't read after I stop pressing the sensor connector. I try using other sensors and still the same. I'm wondering if the connecting part of the power meter has bad contact. Should I open the power meter and change a new connector? swick

(posted 2017-03-06 03:07:53.0) This is a response from Sebastian at Thorlabs. Thank you for the inquiry.

I have contacted you directly for assistance. ww40556

(posted 2016-12-19 22:02:45.42) I'm trying to connect PM100D by Visual C++, following by the Programming Reference, but I can't found the driver page. How could I connect PM100D by Visual C++. Thanks. wskopalik

(posted 2016-12-21 02:59:02.0) This is a response from Wolfgang at Thorlabs. Thank you very much for your inquiry. I am sorry for this issue and have contacted you directly to troubleshoot this in detail. user

(posted 2016-03-07 09:21:29.703) I'm using your device for the real time monitoring of few msec wide optical pulses, therefore I have the same problem as described in the previous message by gbeckford93.

By writing my own application which only requests the data, I have done precise timing tests on your device and found that it is possible to increase the number of samples per second by concatenating multiple "READ?" on the same SCPI command.

As example, by issuing the SCPI command "READ?;READ?;READ?;READ?;READ?" the instrument will respond with a string containing a list of 5 measurement that, if the averaging is set at 1 and auto range is disabled, are separated by 2.338 msec (2.369 msec with auto range enabled) instead of the 3 msec separation that would be obtained by retrieving the measurements by means of consecutive "READ?" in separate SCPI commands.

Unfortunately, the FIFO buffer dedicated to the device output is only 256 bytes and the buffer filling condition is not handled by the firmware so, if the SCPI responce string requires more than 256 bytes, all the exceeding chars will be lost.

Considering then that each measurement is transfered to PC using 15/16 ASCII chars (depending on sign), only up to 16 measurement can be requested on a single SCPI command without the risk of receiving an ASCII string truncated to 256 chars.

By retrieving then arrays of 16 measurements, rather than single values, my application is able to read from your device up to 416 samples per second that (a part a small gaps between the arrays) are equispaced by 2.338 msec

Considering that time requested for ADC conversion is only 0.333 msec, the remaining 2 msec are entirely spent by the device firmware to process the data and could certainly be significantly reduced if two additional SCPI Commands, rather standard in this kind of instruments, were implemented also in your device:

- "CONFigure:ARRay" and "READ:ARRay?"

to setup and retrieve an array of multiple

measurement in a single com shallwig

(posted 2016-03-09 05:34:09.0) This is a response from Stefan at Thorlabs. Thank you very much for your valuable feedback. We will review your ideas and check how we can improve the units here. As you left no contact data, please contact us at europe@thorlabs.com for further questions. gbeckford93

(posted 2016-01-27 14:31:47.583) Does the software currently available (For both single and multiple devices) allow readings of 1kHz? Even with the interval at 0 and the averaging at 1 the most I am able to get is around 300Hz.

If not then how can I increase the samples per second?

Thank you. shallwig

(posted 2016-01-28 06:39:37.0) This is a response from Stefan at Thorlabs. Thank you very much for your inquiry. The sampling speed of the currently available software is limited to around 300 Hz. This limitation has several reasons, mainly from the GUI which queries also the status of the device and sensor and saves the data into a file.This could be bypassed by writing a short own application which only requests the data. In the Software package also drivers for Labview, Visual Basic, C++ and C# are included.

You can download Power meter application notes for programming from the “Programming Reference” Tab http://www.thorlabs.com/software_pages/viewsoftwarepage.cfm?code=PM100x&viewtab=5

Another limitation for getting equidistant data will be the USB connection. Sampling at 1 kHz is possible by using the PM100Ds Analog output. The Bandwidth is DC-100 kHz dependent on the sensor.

I will contact you directly to check your application in more detail. chang.chen

(posted 2015-09-30 16:44:51.837) Hello,

I bought two these powermeters with silicon detectors. But one of the powermeter PM100D didn't work. It shows cannot detect the sensor. I have tested the sensor in the good powermeter, and the sensor works. Is there a way to fix the broken powermeter?

Thanks,

Dr. Chang Chen

imec, Belgium shallwig

(posted 2015-09-30 11:50:28.0) This is a response from Stefan at Thorlabs. Thank you very much for your inquiry. I am sorry for the problems you face with one of your power meters. I will contact you directly to troubleshoot this in detail. eh8423

(posted 2015-09-16 18:32:03.177) I am using the powermeter with some C code to measure the transmission through a device. Halfway through my measurement the powermeter stops working and gives the error that it cannot write to the serial port. Why is this? Am I sampling too fast? shallwig

(posted 2015-09-17 03:48:11.0) This is a response from Stefan at Thorlabs. Thank you very much for your inquiry. I am sorry for the problems you are facing with our device. We will contact you directly to troubleshoot this in detail. jeffb

(posted 2015-05-26 18:29:20.047) Are the S120VC and S120C detectors NIST traceable calibrated for irradiance? The detector aperture is specified as 9.5 mm but is the tolerance of the aperture negligible, calibrated for, or already accounted for in the specs?

thanks! shallwig

(posted 2015-05-27 06:48:28.0) This is a response from Stefan at Thorlabs. Thank you very much for your inquiry. All our detectors are only NIST traceable calibrated in terms of absolute power. The setup we use for calibrating our sensors can be found on our website in the power meter tutorial if you click on the “calibration” Tab: http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=6188

We use a monochromator which has about 2mm beam diameter. Therefore the aperture dimensions and its tolerances are uncritical for the S120VC and S120C. Both have an input aperture of 9.5mm diameter.

First a reference scan is carried out and the reference current (IRef) vs. wavelength is recorded. This allows the calculation of the optical power at each wavelength step. The Reference photodiodes are recalibrated annually at PTB or NIST, which gives the traceability. After that we replace the reference by the diode under test (DuT) and repeat the wavelength scan. This time the current (IDuT) vs. wavelength gets recorded.

During any calibration scan, a monitor diode is used to observe power variations due to lamp aging. The ratio of the actual monitored value during calibration to that during the reference scan is used to correct the calibration scan. As soon as the deviation exceeds 1%, a repeated reference scan is carried out. The responsivity of the DuT is then calculated over the entire specified wavelength range of the DuT with a step size of 5 nm. These data sets (responsivity and wavelength) are saved to the sensor's memory, located in the DSUB connector. Additionally, the calibration data are printed out to the Certificate of Calibration and are saved to our server.

Irradiance you can also display with our power meter consoles by entering the beam diameter. But the given value is a calculation made from the measured optical power and the beams dimensions.

I will contact you directly to discuss your needs in more detail. lhkorea