405 nm Single Mode Two-, Three-, or Four-Color Combiners

- Wavelength Range from 400 - 635 nm

- Combine or Split 405 nm with up to Three Additional Wavelengths in the Visible Spectrum

- Ideal for RGBV Combining Applications

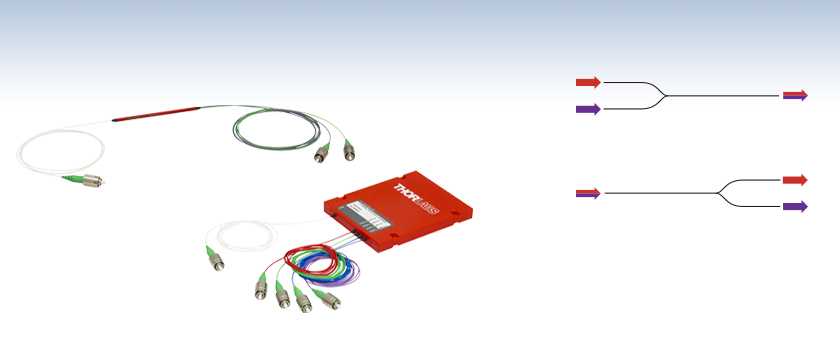

SM 405 nm Two Color Combiner

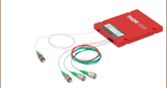

SM 405 nm Four Color Combiner

Combine Wavelengths into a Single Fiber Output

Split Wavelengths from a Single Fiber Input

Please Wait

Contact tech support to discuss your 405 nm application with one of our specialists.

Click for Details

Example image of a 4-color combiner. The ports are labeled with each wavelength. The common port (COM) has a white jacket.

Features

- Contact Us for 405 nm Color Combiners

- Combine or Split 405 nm with up to Three Other Wavelengths

- Wavelength Range: 400 nm to ≥635 nm

- Excellent for Confocal Microscopy, Fluorescence, and Other Applications with Multiple Illumination Sources

- Color Labeled Input Leads for Easy Identification

- Available Unterminated or with 2.0 mm Narrow Key FC/PC or FC/APC Connectors

Thorlabs' fused fiber color combiners, also known as wavelength division multiplexers (WDMs), allow up to four single-mode signals to be combined into a single output fiber. These color combiners are reversible; they can also be used to split up to four wavelengths entering the common port into separate output ports. Due to the short wavelength of 405 nm light, there are additional factors that must be considered when deciding the type of 405 nm WDM that is appropriate for a given application (see the Key Considerations section below). If you are interested in a 405 nm WDM, please contact tech support to discuss your needs with one of our specialists.

Click to Enlarge

Pure Silica Core Fiber

Key Considerations

Fibers

Two different optical fiber designs offer single mode propagation at 405 nm: germanium (Ge) doped and pure silica core fibers. They both typically have an operating wavelength range of 400 to ≥635 nm. For an NA of 0.12, a germanium-doped fiber will have a core of Ø2.1 µm. For the same NA, the pure silica core fiber will have a core of Ø3.0 µm.

Core Size

The core diameter necessary for single mode operation at 405 nm is more than three times smaller than for a 1550 nm fiber such as Corning SMF-28. Due to their very small core sizes, these fibers need to be centered to extremely tight tolerances when terminated with FC/PC or FC/APC optical connector ferrules. When connectors are mated together, such as in a bulkhead, any misalignment of the fiber cores can create significant optical losses. Furthermore, splicing of small core SM optical fibers requires specialized equipment for optimal results.

Attenuation

Fibers that guide 405 nm light are inherently more lossy than traditional NIR/Telecom optical fibers. As an example, fiber used to transmit 1550 nm light will have an attenuation of ≤0.15 dB/km whereas fiber used to transmit 405 nm light will typically have an attenuation of ≤30 dB/km.

Facet Damage

Due to the small fiber core size, single mode fiber facets will be exposed to intense 405 nm radiation. 5 mW of CW light in a 3 µm pure silica core fiber represents a power density of 70.7 kW/cm² whereas the same power in a 2.1 µm Ge doped core has a power density of 144.4 kW/cm². Any dirt, grime, or grease on the fiber facet will also be exposed to this intense flux of light and as it undergoes chemical breakdown, could potentially damage the fiber or increase the attenuation in the light path to unacceptable levels. Due to the larger core diameter of pure core silica fibers, they are less susceptible to fiber facet damage than Ge doped fibers. It is generally recommended to use pure core silica fibers for powers above 5 to 10 mW.

Color Center Formation

Optical fibers can experience photo-induced absorption (photo darkening) when they are exposed to 405 nm light. This means that the attenuation resulting from absorption or scattering will increase over time. The color center formation mechanism will create microscopic defects in the fiber by the interaction of light with dopants or impurities present in the fiber, as well as with strained molecular bonds created during the fiber drawing process. It is dependent on the type of fiber, the wavelength and intensity of the light as well as the exposure time. The effect is cumulative but in certain cases can be reversible. Photodarkening can have a significant impact on the performance of any fiber or fiber-based optical device used at 405 nm often to the point where the fiber becomes unusable. Pure silica core fibers have a higher resistance to color center creation as compared to germanium-doped fibers.

Thorlabs offers a variety of 405 nm WDMs that can be used to combine a 405 nm input with other wavelengths in the visible spectrum, as well as single mode couplers for combining or separating multiple 405 nm signals. For more information, please contact us. We will be pleased to work with you to determine whether our 405 nm components are appropriate for your applications and what their expected performance may be on delivery and over their lifetime.

| Alternative Fiber Coupler & Splitter Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Double-Clad Couplers | Single Mode Couplers | Single Mode PLC Splitters | Multimode Couplers | Polarization-Maintaining Couplers | Wavelength Division Multiplexers (WDM) |

|||||

| 2x2 | 1x2 | 2x2 | 1x4 | 1x8 | 1x16 | 1x2 | 2x2 | 1x2 | 2x2 | |

Wavelength Division Multiplexer Design

Thorlabs' Wavelength Division Multiplexers (WDMs) are designed to combine or split light at two different wavelengths. Thorlabs offers a variety of multiplexers with wavelength combinations spanning the visible, near-IR, and IR regions of the spectrum. Our visible wavelength division multiplexers are also known as "wavelength combiners" as they are commonly used in microscopy applications to generate multi-color composite images.

The animation to the right illustrates the basic operating principles of a 1x2 WDM. When combining light, the wavelength-specific ports will transmit light within a specified bandwidth region and combine them into a multi-wavelength signal output at the common port, with minimal loss in signal.

Except where indicated, our WDMs are bidirectional; they can also split a two-wavelength signal that is inserted into the common port into the component wavelengths. For optimal combining/splitting performance, the input signal(s) should contain only the wavelengths specified for the WDM. An insertion loss graph can help estimate the transmission and coupling performance within and outside the specified bandwidth. For our WDMs that have red, engraved housings, this data is included with the item-specific datasheet that ships with each coupler.

Click to Enlarge

The shaded regions in the plot indicate the bandwidth where each port meets the specified performance.

Insertion Loss and Isolation

WDM performance is typically quantified using insertion loss. As seen in the definition below, insertion loss (measured in dB) is the ratio of the input power to the output power from each leg of the WDM. For optical systems, the definition of insertion loss is given as:

where Pin and Pout are the input and output powers (in mW).

Each port of the coupler is designed to have low insertion loss (i.e., high transmission) at the desired wavelength while suppressing the signal at the specified wavelength of the other port, which minimizes cross talk between the ports. Therefore, isolation is specified as the insertion loss of these undesired wavelengths. High dB values of isolation are ideal for signal separation applications using a WDM. For example, in the graph shown to the right, the long wavelength port (shown using a red dashed line) has a low insertion loss around 640 nm (indicated by the red shaded region), but exhibits high isolation (>25 dB) in the region specified for the short wavelength port (indicated by the light blue shaded region).

Wavelength Division Multiplexer Manufacturing Process

This section details the steps used in manufacturing and verifying the performance of our wavelength division multiplexers.

Click to Enlarge

In the diagram, the fibers are color-coded; blue for the short wavelength port and red for the long wavelength port.

Step 1

At the first stage, two fibers are fused on a manufacturing station so that the two fiber cores are in close proximity. This allows light to propagate between the two fiber cores over the fused region in a process known as evanescent coupling. The fusing process is stopped once the desired insertion loss and isolation specifications are achieved.

The output from the short wavelength port is monitored during the fusing process using a broadband source on one side and an optical spectrum analyzer (OSA) on the other. The insertion loss as a function of wavelength is calculated from the spectrum obtained from the OSA.

Click to Enlarge

In the diagram, the fibers are color-coded; blue for the short wavelength port and red for the long wavelength port.

Step 2

To verify the WDM performance, the output is measured in the long wavelength port using a broadband source and OSA. By combining the plots obtained in steps 1 and 2, the insertion loss and isolation in each channel can be calculated.

| Posted Comments: | |

Jalal Baruni

(posted 2023-01-16 12:51:20.373) I feel like a 473 and around 590 nm combiner/splitter would be a very popular combo given use in optogenetics and fiber photometry jgreschler

(posted 2023-01-17 09:08:54.0) Thank you for reaching out to Thorlabs. Custom wavelength configurations can be requested by contacting techsupport@thorlabs.com. I have reached out to you directly to discuss your specific application. |

Products Home

Products Home

UV/Visible, 2-, 3-, or 4-Wavelength, SM WDMs

UV/Visible, 2-, 3-, or 4-Wavelength, SM WDMs