SM1-Compatible Translation Mounts

- Mounts Ø1" Optics and Lens Tubes

- Internal SM1 Threading (1.035"-40)

ST1XY-D

Mount with 6 mm

X and Y Travel

LM1XY

Post-Mountable

XY Translator

SPT1N

XY Slip-Plate

Positioner

CT1A

30 mm Cage

Translation Stage

SM1ZA

Cage Compatible Z-Axis Translation Mount

CXY1A

XY Translation Mount for Ø1" Optics

Please Wait

| SM1-Compatible Translation Mount Options Available |

|---|

| XY-Axes Translation Mounts |

| XYZ-Axes Translation Mount |

| Z-Axis Translation Mounts |

This page is a compilation of all of the SM1-threaded (1.035"-40) translation mounts sold by Thorlabs in order to allow for the quick selection of a translation mount if SM1 threading is a primary requirement. Thorlabs also has similar compilations of SM-threaded translation mounts for Ø1/2" (12.7 mm) and Ø2" (50 mm) optics. If SM threading is not a primary requirement for the translation mount, consider using the manual translation mount navigation menu.

| Posted Comments: | |

user

(posted 2023-11-23 19:13:22.083) Would it matter if the knob of the SM1ZA on top or bottom? cdolbashian

(posted 2023-11-29 02:20:32.0) Thank you for reaching out to us with this inquiry. There shouldn't be a difference in performance, as long as the device is still translating horizontally. Christian Schmidt

(posted 2020-06-22 04:28:14.01) Hello Thorlabs Team,

I want to utilize 1" lenses in a 30 mm cage system. What are the advantages/drawbacks of CT1 and SM1Z ragarding machanical stability and vibrations?

Many Thanks llamb

(posted 2020-06-25 11:39:16.0) Hello, thank you for contacting Thorlabs. The CT1 features a spring-loaded precision ball bearing decision, which is often more susceptible to external vibrations because of more internal components when compared to the simpler flexure plate design of the SM1Z. However, CT1 features a locking plate to secure a position, while the SM1Z does not. I have reached out to you directly to discuss which of these products will best suit your application. user

(posted 2016-08-25 17:19:38.397) The face of the CXY1 gives the impression you can rotate the optic (within the confines of the cage rods of course). Is this true? If so, can it rotate during translation as noted for the LM1XY? I see the "designed for pure X and Y translation" note but it's unclear if this is different than the LM1XY.

Thank you. milankie

(posted 2013-05-30 15:37:00.187) are the differential screws in this product 1/4'' or 3/8'' wide? If they are 1/4'', are the ST1XY-M 3/8'' wide? most motorized actuators are 3/8'' wide, which is why I ask. jlow

(posted 2013-05-30 16:47:00.0) Response from Jeremy at Thorlabs: The differential drives have 1/4"-80 thread. The ST1XY-S uses a micrometer with Ø6mm barrel. It seems that you are looking for a motorized version of this. We could make a custom one using our Z806 motor. I will contact you directly regarding this option. |

- High-Resolution Adjusters Provide 250 µm/rev for Micron Sensitivity

- Designed to Center Ø1" Optics in a Beam Path

- Internal SM1 (1.035"-40) Threading for Compatibility with Our Extensive Line of SM1 Lens Tubes

- Tip/Tilt Deviation: <100 µrad

- 8-32 (M4) Tapped Hole for Post Mounting

The LM1XY(/M) translation mount utilizes M3 x 0.25 fine adjustment screws to provide ±1 mm of travel perpendicular to the optical axis. The adjustment screws provide 250 µm/rev and feature a 5/64" hex for fine adjustments. This translation mount is internally SM1 threaded (1.035"-40) for use with our line of SM1-threaded components. The LM1XY holds Ø1" optics, up to 0.32" (8.0 mm) thick, against the back lip of the mount, using the provided SM1RR retaining ring.

Please note that the moving SM1-threaded world may be manually rotated and may also rotate during translation.

- Accepts Ø1.00" Optics up to 0.48" (12.2 mm) Thick

- Compact Design, ±0.12" (±3.0 mm) Travel

- Compatible with Our Ø1" SM1 Lens Tubes

- 4-40 Taps on Front and Back Provide 30 mm Cage Compatibility

The ST1XY translation mounts offer ±3.0 mm of travel provided by one of three drive types: adjuster screw, micrometer, or differential drive. They utilize hardened tool steel components on all moving parts to ensure long-term, drift-free operation. The ST1XY is designed to connect with our extensive line of Ø1" SM1 Lens Tubes as well as our 30 mm cage assemblies to offer great flexibility when building optical systems.

The translating SM1-threaded carriage accepts optics up to 0.48" (12.2 mm) thick when using two SM1RR retaining rings (included). A stationary internal SM1 thread with 0.14" (3.5 mm) depth is present on the other side of the mount that allows for coupling to stationary SM1 Lens Tubes.

Three 8-32 (M4) tapped holes are provided on the bottom surface to allow direct mounting on our Ø1/2" Posts.

| Item # | Travel | Drive Type |

Drive Mechanism | Optic Mounting |

Post Mounting |

ER Cage Rod Connection |

|---|---|---|---|---|---|---|

| ST1XY-A(/M) | ±0.12" (±3.0 mm) | 100 TPI | 0.01" (0.25 mm) per Revolution and 100 Threads per Inch Adjusters (Locking Set Screw on Each Adjuster Uses 0.035" Hex Key) |

SM1 (1.035"-40) Thread |

Three 8-32 (M4) Tapped Holes on Bottom Surface |

4-40 Tapped Holes or Counterbored Mounting Using ST1CP |

| ST1XY-S(/M) | Micrometer | 0.5 mm per Revolution and 10 µm per Graduation Micrometer Screws | ||||

| ST1XY-D(/M) | Differential | 0.4 mm per Revolution Coarse and 25 µm per Revolution Fine Control with 0.5 µm per Graduation Differential Micrometers |

- Accepts Ø1.00" (Ø25.4 mm) Optics up to 0.39" (10.0 mm) Thick

- ±1 mm Travel in X and Y via 3/16"-100 Adjusters

- Compatible with 30 mm Cage Systems

- SM1 (1.035"-40) Threading for Compatibility with Our Extensive Line of SM1 Lens Tubes

The CXY1A XY Translator provides ±1 mm of travel perpendicular to the optical axis of a 30 mm cage system. This translation is actuated by two 3/16"-100 adjusters, which are lockable via a 0.035" hex key. The movable carriage is internally SM1 (1.035"-40) threaded and directly accepts Ø1" optics up to 0.39" (10.0 mm) thick when secured using the included SM1RR retaining ring. The fixed back side is also threaded to allow SM1 lens tubes to be attached. The center carriage has been designed to offer pure X and Y translation. The mount features engraved vertical and horizontal tick marks to use as an alignment aid for the mounting carriage.

The translation mount also features four through holes for use with our ER cage rods. One side-located M4 x 0.7 locking setscrew in each bore can be tightened using a 5/64" (2.0 mm) hex key to secure a cage rod.

| Item # | Travel | Drive | Optic Mounting | ER Cage Rod Connection |

|---|---|---|---|---|

| CXY1A | ±1 mm | 100 Threads per Inch (TPI) Adjusters | SM1 (1.035"-40) Thread | Through Holes with Side-Located Locking Screws |

Click to Enlarge

Click to EnlargeCXY1QA mount is shown above integrated into a 30 mm cage system. Engraved circles indicate the correct orientation of the quick-release carriage. A white space for writing in the name of optic is located on the side of the CXY1QF plate.

- Accepts Ø1.00" (Ø25.4 mm) Optics

- ±1 mm Travel in X and Y via 3/16"-100 Adjusters

- Magnetically Coupled, Quick-Release Mounting Carriage (Extra Carriages Sold Separately)

- Compatible with 30 mm Cage Systems

- SM1 (1.035"-40) Threading for Compatibility with Our Extensive Line of SM1 Lens Tubes

The CXY1QA XY Translation Mount is similar to the CXY1A mount sold above, but features a quick-release mounting carriage for easy exchange of components within a 30 mm Cage System. This mount provides ±1 mm of travel perpendicular to the optical axis of a 30 mm cage system. This translation is actuated by two 3/16"-100 lockable adjusters. The movable center carriage and magnetically coupled mounting carriage are internally SM1 (1.035"-40) threaded and directly accept Ø1" optics up to

0.39" (10.0 mm) and 0.20" (5.0 mm) thick, respectively, when secured using the included SM1RR retaining ring. The fixed back side is also threaded to allow SM1 lens tubes to be attached. The center carriage has been designed to offer pure X and Y translation.

The mount features engraved vertical and horizontal tick marks to use as an alignment aid for the movable carriage. A dot is engraved on both pieces of the mount to indicate the correct orientation of the quick-release carriage. Aligning the dots ensures the quick-release carriage is properly secured. The quick-release carriage also features a dedicated white space for denoting the optic that has been mounted within it (see the photo to the right). This allows for easy identification if more than one carriage is being used in a setup, as extra CXY1QF quick-release carriages can be purchased separately.

The translation mount also features four through holes for use with our ER cage rods. One side-located M4 x 0.7 locking setscrew in each bore can be tightened using a 5/64" (2.0 mm) hex key to secure a cage rod.

To remove the quick-release carriage from the mount when in a closed cage system, detach the carriage, rotate it 90°, and then take it out of the system. There must be at least 1.60" (40.6 mm) separating the edge of the quick-release carriage and the next component in the system to provide enough clearance during removal.

| Item # | Travel | Drive | Optic Mounting | Torque Applied to CXY1QF | ER Cage Rod Connection |

|---|---|---|---|---|---|

| CXY1QA | ±1 mm | 100 Threads per Inch (TPI) Adjusters | SM1 (1.035"-40) Thread | 0.58 in-lb (0.0655 N•m)a | Through Holes with Side-Located Locking Screws |

Click to Enlarge

Click to EnlargeSM1-threaded lens tubes can be threaded onto both the front and back plate of the SPT1N slip plate mount.

- ±0.04" (±1 mm) of Coarse Adjustment in Both X and Y Directions

- Center-Located SM1 (1.035"-40) Threaded Hole in Front Adjustment Plate and Back Plate

- Position Front Plate by Hand and Lock in Place by Tightening Locking Screws with 5/64" (2 mm) Hex Key

- Secure Back Plate to a Ø1/2" Post via the Bottom-Located 8-32 (M4) Tap

The SPT1N(/M) Slip Plate Positioner is designed to provide coarse XY positioning of optical components. Both the front slip plate and back plate feature a center-located SM1-threaded hole ideal for use with our SM1 Lens Tubes. This design provides for manual adjustment only and is best utilized in conjunction with an alignment laser to monitor centricity. The threaded front plate is spring-loaded against the fixed, threaded back plate and can be locked into position via two locking screws. These locking screws can be threaded into the front side of the mount, or they can be removed and then re-threaded into the back side.

The front slip plate of the SPT1N(/M) accommodates Ø1" optics up to 0.07" (1.8 mm) thick, while the thicker back plate can hold Ø1" optics up to 0.19" (4.8 mm) thick. Unmounted optics can be secured with two SM1RR Retaining Rings (not included). The center-located SM1 (1.035"-40) tapped through holes in both the front and back plates also directly accept externally SM1-threaded components. Components should not be threaded past the end of either plate, as this will prevent the front slip plate from working properly. Please see the table below for the individual plate thicknesses.

| Item # | Travel | Front Slip Plate Thickness |

Back Plate Thickness |

Front Plate Maximum Optic Thickness |

Back Plate Maximum Optic Thickness |

Optic Mounting |

Post Mounting |

|---|---|---|---|---|---|---|---|

| SPT1N(/M) | ±0.04" (±1 mm) | 0.23" (5.8 mm) | 0.35" (8.9 mm) | 0.07" (1.8 mm) | 0.19" (4.8 mm) | 2 SM1RR Retaining Rings SM1-Threaded (1.035"-40) Bore |

8-32 (M4) Tap on Bottom Surface |

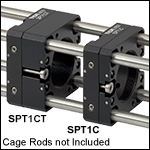

Click to Enlarge

The SPT1CT and SPT1C Slip Plates assembled in a cage system using the ER series cage rods.

- ±0.04" (±1.0 mm) of Adjustment in Both X and Y Directions

- Center-Located SM1 (1.035"-40) Threaded Hole in Front Slip Plate and Smooth Bore in Fixed Back Plate

- Position Front Plate by Hand and Lock in Place by Tightening Locking Screws

- Secure Back Plate to Four Cage Rods via Side-Located Setscrews

- 8-32 (M4) Threaded Hole in Base of Back Plate for Post Mounting

The SPT1C(/M) and SPT1CT(/M) Slip Plate Positioners are designed to provide coarse XY positioning of optical components within our 30 mm Cage Assembly System. This design provides for manual adjustment only and is best utilized in conjunction with an alignment laser to monitor centricity. The front plate can be locked into position against the fixed plate via two locking screws, which can be tightened using a 5/64" (2 mm) hex key.

The SPT1C(/M) slip plate accomodates Ø1" optics up to 0.08" (2.0 mm) thick, while the thicker front plate on the SPT1CT(/M) can hold Ø1" optics up to 0.34" (8.6 mm) thick. Unmounted optics can be secured with SM1RR Retaining Rings, two of which are included with the SPT1CT(/M). The center-located SM1 (1.035"-40) tapped through hole also directly accepts externally SM1-threaded components. Four through holes in the back plate of each mount with side-located locking screws accept ER series cage rods for compatibility with our 30 mm cage systems.

| Item # | Travel | Slip Plate Thickness | Maximum Optic Thickness | Optic Mounting | Post Mounting | ER Cage Rod Attachment |

|---|---|---|---|---|---|---|

| SPT1C(/M) | ±0.04" (±1.0 mm) |

0.23" (5.8 mm) | 0.08" (2.0 mm) | SM1 (1.035"-40) Thread |

8-32 (M4 x 0.7) Tap on Bottom Surface |

4 Through Holes with Side-Located Locking Screws, 5/64" (2 mm) Hex |

| SPT1CT(/M) | 0.50" (12.7 mm) | 0.34" (8.6 mm) |

| Specifications | |

|---|---|

| X and Y Axis Drivers | 1/4"-100 Adjustersa |

| XY Travel | ±2.5 mm (±0.10") per Axis |

| XY Adjustment Resolution | 254 µm/rev |

| Z-Axis Driver | 500 µm/rev Adjustment Dialb |

| Z Travel | ±1.5 mm (±0.06") (Alignment Tick Marks at 0.25 mm Intervals) |

| Clear Aperturec | Ø0.90" (Ø22.9 mm) |

| Optic Thickness (Max) | 0.39" (10.0 mm) |

| Optic Mounting | Internal SM1 (1.035"-40) Thread |

| Post Mountingd | Two 1/4"-20 (M6) Tapped Holes (Allows Right- and Left-Handed Orientations) |

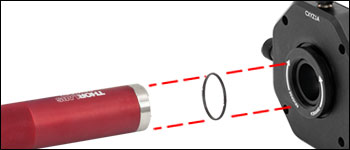

Click to Enlarge

Translation of the Z-Axis Carrier Achieved by Rotating the Engraved Adjustment Dial

- Accepts Ø1" (Ø25.4 mm) Optics up to 0.39" (10.0 mm) Thick

- 60 mm Cage Compatible and Post-Mountable

- SM1 (1.035"-40) Threading for Compatibility with Our Extensive Line of SM1 Lens Tubes

- Two 1/4"-20 (M6) Tapped Holes for Post Mounting

Thorlabs' CXYZ1A(/M) Translation Mount features X-, Y-, and Z-axis travel and holds Ø1" optics, up to 0.39" (10.0 mm) thick, against the back lip of the mount using the provided SM1RR retaining ring. The XY functionality allows travel perpendicular to the optical axis, while the Z-axis functionality allows for compensation of focusing errors in applications such as fiber alignment or lens mounting. The optic cell has been designed to offer pure X, Y, and Z translation.

Click to Enlarge

The Z-axis position can be locked by threading an SM30RR retaining ring (sold separately) onto the internal threads of the rear knurled knob. This can be done using the SPW607 Spanner Wrench.

The optic cell is internally SM1 (1.035"-40) threaded and is translated along the Z-axis by rotating the zoom adjustment dial on the back of the mount. The optic cell does not rotate during translation. An engraving is included on the knurled dial, indicating the direction that it must be turned for translating the optic cell forward and backwards. Laser-engraved tick marks spaced 0.25 mm apart are included on the optic cell for indicating the Z-axis position. The position can be locked using an SM30RR Retaining Ring (sold separately); see the image to the right for more details.

X and Y translation of the optic cell is actuated using the two 1/4"-100 fine adjusters, which can be locked using our LN25100 Locking Nuts (sold separately). Horizontal and vertical witness lines provide a reference for the XY alignment.

The mount has four through holes on 60 mm centers for use with our Ø6 mm ER cage rods, making it compatible with our 60 mm Cage Systems. Each cage rod mounting hole has one side-located locking setscrew, which use a 5/64" (2.0 mm) hex key or balldriver. The mount can easily be adapted to 30 mm Cage Systems by using the LCP33 Cage System Size Adapter. Two 1/4"-20 (M6) tapped holes are also provided on opposite sides of the XY adjusters for post mounting in right- or left-handed orientations.

Thorlabs also offers a 30-mm-cage-compatible XYZ translation mount for Ø1/2" optics, available here.

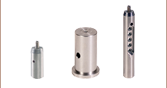

Click to Enlarge

1/4"-20 Mounting Tap Being Used to Mount the SM1ZP from Bottom on a Ø1" Post

- Post-Mountable via 8-32 (M4) and 1/4"-20 (M6) Taps

- Mount Ø1" Optics up to 0.28" (7.1 mm) Thick

- Flexure Design Provides 2.0 mm (0.079") of Travel

- Actuator Knob Graduated in 1 µm Increments

- SM1-Threaded (1.035"-40) Bore is Compatible with Our SM1 Lens Tubes

Thorlabs' SM1ZP(/M) Translation Mount offers repeatable, flexure-actuated, Z-axis travel. It includes two SM1RR retaining rings for holding a Ø1" (25.4 mm) optic up to 0.28" (7.1 mm) thick. This allows for compensation of focusing errors in applications such as fiber alignment or spatial filtering.

The lens carriage is internally SM1 (1.035"-40) threaded and is translated using the precision micrometer actuator, which is graduated in 1 µm increments. The micrometer can be actuated using the knurled knob or a 5/64" (2 mm) hex key. This threaded carriage allows for thicker optics to be mounted to the SM1ZP using our SM1 lens tubes, as shown in the image to the right. When mounted from the bottom, the center of the lens carriage is 2.00" (50.0 mm for SM1ZP/M) from the top of the post, while when mounted on its side, it is 0.68" (17.1 mm) from the top of the post.

The mount contains three 8-32 (M4) taps and two 1/4"-20 (M6) taps on its base as well as two 8-32 (M4) taps on its side for mounting onto any Ø1/2", Ø1", or Ø1.5" Post, as shown in the images above.

| Item # | Optic Size Accommodated | Maximum Optic Thickness | Travel | Travel per Revolution | Optic Mounting | Mounting |

|---|---|---|---|---|---|---|

| SM1ZP(/M) | Ø1" | 0.28" (7.1 mm) | 2.00 ± 0.07 mm (0.079" ± 0.003") | 50 μm/rev | 2 SM1RR Retaining Rings SM1 (1.035"-40) Thread |

Side: Two 8-32 (M4) Taps Bottom: Three 8-32 (M4) and Two 1/4"-20 (M6) Taps |

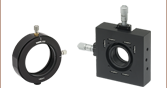

- Compatible with 30 mm Cage Systems

- Mount Ø1" Optics up to 0.28" (7.1 mm) Thick

- Flexure Design Provides 2.0 mm (0.08") of Travel

- Actuator Knob Graduated in 1 µm Increments

- SM1-Threaded (1.035"-40) Bore is Compatible with Our SM1 Lens Tubes

Thorlabs' SM1ZA Translation Mount offers repeatable Z-Axis travel within a 30 mm cage system. It includes two SM1RR retaining rings for holding a Ø1" (25.4 mm) optic up to 0.28" (7.1 mm) thick. This allows for compensation of focusing errors in applications such as fiber alignment or spatial filtering within a cage system or for applications that require fine adjustment along the optical axis.

The lens carriage is internally SM1 (1.035"-40) threaded and is translated using the precision micrometer actuator, which is graduated in 1 µm increments. The micrometer can be actuated using the knurled knob. Coarse movement is achieved by sliding the SM1ZA along the rods of a 30 mm cage assembly. Once positioned, tighten four M4 x 0.7 setscrews [5/64" (2.0 mm) hex] to apply locking force to the cage rods, firmly holding the mount in place. The threaded carriage allows for thicker optics to be mounted to the SM1ZA using our SM1 lens tubes.

For cage assemblies requiring a longer translation range along the optical axis, Thorlabs offers the CT1A(/M) stage capable of a full 1/2" (13 mm) of travel.

| Item # | Optic Size Accommodated | Maximum Optic Thickness | Travel | Travel per Revolution | Optic Mounting | Mounting |

|---|---|---|---|---|---|---|

| SM1ZA | Ø1" | 0.28" (7.1 mm) | 2.0 mm (0.08") | 50 μm/rev | 2 SM1RR Retaining Rings SM1 (1.035"-40) Thread |

Through Holes with Side-Located Locking Screws for 30 mm Cage System |

Click to Enlarge

CT1A Translation Stage Shown Assembled in a 30 mm Cage System

- Maximum Stage Travel: 1/2" (13 mm)

- Micrometer Drive with 0.001" (10 µm) per Graduation

- Material: Aluminum with Hardened Steel V-Grooves

- Bearing Type: Ball Bearing

- Comes with CT101: Ø1" Optic Mount

- Lockable Design

The CT1A(/M) Manual Translation Stage is designed to be utilized within 30 mm cage systems requiring translation along the optical axis of the cage. The stage includes a Ø1" optic mount, which has internal SM1 threading (1.035"-40) for mounting Ø1" optical components up to 0.27" (6.9 mm) thick, or externally SM1-threaded components, such as our SM1 lens tubes. The CT1A(/M) translation stage is modular and we also offer a series of alternative mounts for the movable carriage.

Precision linear ball bearings are used to ensure smooth high resolution motion. The CT1A(/M) includes a graduated micrometer, which provides 1/2" (13 mm) of linear translation with 0.001" (10 μm) graduations. A 5/64" (2 mm) hex on the micrometer allows for actuation in space-constrained environments. One SM1RR retaining ring is included with each unit.

Products Home

Products Home

Zoom

Zoom

SM1-Compatible Translation Mounts

SM1-Compatible Translation Mounts